Moving heavy loads isn’t just about muscle; it’s about the wheels beneath you. Choosing between tires can determine whether you’re gliding over obstacles or fighting vibration, flats, and control issues.

Recent OSHA data shows that workers in warehousing and material-handling are among the most injury-prone in the country. In fact, slips, trips, and falls make up about 27% of all non-fatal warehouse accidents.

So let’s break down the real difference between pneumatic or rubber tires for a hand truck, and how to choose confidently.

Quick Take:

Match to Terrain: Pneumatic tires excel outdoors and on uneven surfaces; solid rubber tires perform best on smooth indoor floors.

Load Protection vs Stability: Pneumatic cushioning protects fragile loads; solid rubber offers firm stability for heavy, stacked cargo.

Maintenance Expectations: Pneumatic requires air checks and repairs; solid rubber delivers zero-maintenance performance with no flats or downtime.

Operational Cost Efficiency: Choosing the right pneumatic or rubber tires for a hand truck reduces fatigue, prevents damage, and lowers lifetime operating costs.

Industry Fit: Pneumatic is ideal for hospitals and delivery routes; solid rubber suits assembly lines, warehouses, and food washdown areas.

Expert Support: Humphries Casters provides tailored recommendations, OEM-equivalent options, and bulk procurement to ensure the best tire decision.

A Quick Look at Both Tire Types

Before you pick a side in the pneumatic vs rubber debate, you need to understand what each tire type really brings to the table. Here’s a quick, straight-to-the-point look at how pneumatic and solid rubber tires for hand trucks are built and where they’re most effective, so the differences ahead make perfect sense.

Let’s start with pneumatic tires.

What Are Pneumatic Tires?

Pneumatic tires are air-filled wheels, similar to the tires on bicycles or cars. They use internal air pressure to create cushioning, which helps absorb shock and reduce vibration when rolling over rough or uneven surfaces. On a hand truck, this means smoother handling, better control, and increased protection for delicate or fragile loads.

If you regularly move items outdoors, over curbs, gravel, or cracked pavement, pneumatic tires are designed to make that job significantly easier and safer.

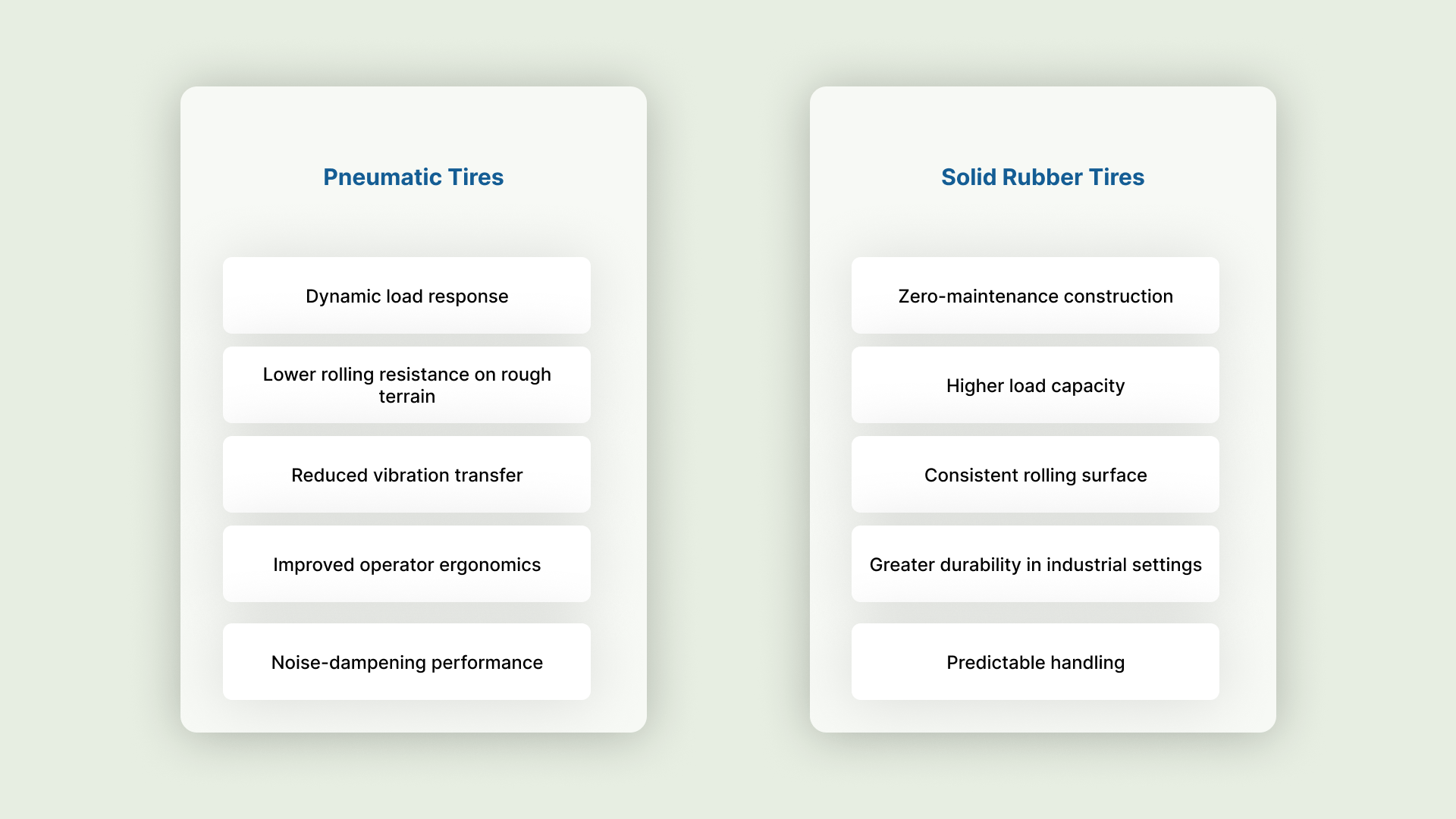

Key Traits

Dynamic load response — the air chamber adjusts under weight, allowing the tire to contour to surface irregularities rather than resisting them rigidly.

Lower rolling resistance on rough terrain — requires less force to move the truck across obstacles like gravel, expansion joints, or uneven pavement.

Reduced vibration transfer — protects internal bearings and axles from long-term stress and premature wear.

Improved operator ergonomics — minimizes hand-arm fatigue and strain during long hauls or frequent use, especially with heavy loads.

Noise-dampening performance — significantly quieter in environments where clattering wheels can be disruptive (e.g., hospitals, schools, residential delivery routes).

What Are Solid Rubber Tires?

Solid rubber tires are airless, fully molded wheels made from durable rubber compounds that don’t rely on inflation to support weight or absorb impact. Because they contain no air chamber, they can’t go flat, leak, or rupture, making them a highly reliable choice for environments where equipment must work consistently without interruption.

On a hand truck, solid rubber tires deliver stable performance, strong weight support, and long-term durability. They perform best on smooth indoor surfaces such as warehouse floors, loading docks, and production facility equipment.

Key Traits

Zero-maintenance construction — no air pressure checks, refills, or puncture repairs required.

Higher load capacity — rigid structure distributes weight more evenly, supporting heavier and more frequent material moves.

Consistent rolling surface — maintains shape under stress, reducing wobble and improving stability during fast or repetitive transport cycles.

Greater durability in industrial settings — resistant to cuts, chemicals, and abrasive surfaces commonly found in warehouses and factories.

Predictable handling — offers firm, uniform contact with the floor, which improves control when transporting stacked or awkward loads.

Now that you know what sets pneumatic and solid rubber tires apart at a basic level, let’s look at the key differences side by side.

Pneumatic vs Rubber Tires: Key Differences

When it comes down to real-life performance, pneumatic and solid rubber tires behave very differently under load, across terrain, and over time. The right choice depends on factors like surface conditions, durability requirements, and how much maintenance you’re willing to handle.

The comparison below breaks down the key differences side by side so you can quickly see which tire type is the best fit for your hand truck and workload.

Decision Factor | Pneumatic Tires | Solid Rubber Tires |

Terrain Advantage | You handle uneven, outdoor, or mixed surfaces with less effort. | You get consistent control over smooth indoor floors. |

Force Required to Move | You push with less force across rough ground due to the air-cushioned roll. | You push harder over bumps, but movement stays steady on flat surfaces. |

Load Stability | You protect delicate or vibration-sensitive loads from shock. | You stabilize stacked or tall loads that need a firm, rigid base. |

Downtime Risk | You accept potential flats and air-pressure checks during busy operations. | You eliminate unexpected stops due to punctures or deflation. |

Operational Environment Fit | You work in delivery paths, construction sites, driveways, and docks. | You work in warehouses, manufacturing floors, and distribution centers. |

Operator Fatigue | You reduce strain and hand-arm vibration on long hauls. | You feel more vibration, but enjoy predictable, rigid handling. |

Lifecycle ROI | You trade a lower initial cost for more upkeep or replacements. | You invest more upfront for long-term durability and repeat use. |

The right choice depends on where you operate, what you haul, and how much maintenance you’re willing to take on.

How to Choose the Right Tires for Your Hand Truck?

There isn’t a one-size-fits-all answer; the right tire choice depends on what challenges you’re solving. Instead of asking which type is “better,” ask where performance matters most for your operation: control on uneven ground, reliability during heavy cycles, or stability under stacked loads.

To narrow it down quickly, walk through the key factors below and see which tire type aligns most closely with how you actually use your hand truck.

Decision Factor | Choose Pneumatic Tires If… | Choose Solid Rubber Tires If… |

Primary Environment | You work outdoors or across mixed terrain like curbs, ramps, gravel, docks. | You operate mainly indoors on smooth warehouse floors or factory surfaces. |

Load Type | You move fragile or vibration-sensitive items that need cushioning. | You haul dense, heavy, stacked, or awkward loads that need a rigid, stable base. |

Usage Frequency | You use a hand truck occasionally or in varied conditions. | You run high-volume, daily cycles where uptime and consistency matter. |

Maintenance Tolerance | You don’t mind checking air pressure or repairing flats. | You want a zero-maintenance solution with no chance of downtime. |

Long-Term Cost Strategy | You prioritize operator comfort and reduced strain. | You prioritize durability and lifecycle value for repeat industrial use. |

Choosing between pneumatic or rubber tires for hand truck setups becomes clearer when you look at real applications. Pneumatic tires are ideal in hospital settings where supply carts or oxygen units must cross rough thresholds or outdoor paths without jarring sensitive equipment.

On assembly lines, solid rubber tires excel by supporting heavy, repetitive loads without downtime. And in food-processing or washdown environments, solid rubber tires resist moisture and chemicals that would quickly damage pneumatics.

When you match tire design to real working conditions, performance, safety, and efficiency all improve, and the right choice becomes obvious.

Where Humphries Casters Comes In

Choosing the right tire type is easier when you have a knowledgeable supplier who understands real-world material-handling challenges. That’s where Humphries Casters stands out. With decades of industry experience and access to a massive range of caster and wheel solutions, they help businesses match the right tires to the right environments.

Instead of guessing between pneumatic or rubber tires for a hand truck, you get expert recommendations based on actual operating conditions.

What You Can Expect from Humphries Casters

Extensive product range — from pneumatic hand-truck wheels to heavy-duty solid rubber wheels for industrial use.

Application-based guidance — recommendations tailored to your terrain, load profiles, and operational demands.

Custom and speciality solutions — options for unique environments such as high-impact routes, medical facilities, or corrosive/wet settings.

Reliable performance products — designed for long lifecycle value, reduced maintenance, and fewer equipment failures.

Bulk and replacement support — ideal for businesses standardizing equipment or upgrading from inconsistent wheel performance.

Humphries Casters ensures your equipment rolls the way it should: smoothly, safely, and reliably.

Conclusion

The right tire choice affects everything from operator fatigue to product integrity to the pace at which work moves. Instead of treating tires as an afterthought, they’re worth evaluating the same way you’d assess any other critical equipment decision: based on real operational pressures, not assumptions.

For support tailored to your facility and load demands, Humphries Casters will help you determine whether pneumatic or rubber tires for a hand truck are the best fit.

Have questions or need tailored recommendations? Reach out to us and get expert support that keeps your operation moving confidently.

FAQs

1. Will switching to the wrong tire type slow down productivity or delivery speed?

Yes. Choosing the wrong pneumatic or rubber tires for hand truck setups can increase travel time, especially if your routes don’t match the wheel design. For example, solid rubber on rough outdoor terrain forces slower movement to maintain control, while pneumatic tires indoors may add friction and reduce pace compared to a firm rubber roll.

2. How do tires impact worker fatigue and long-term ergonomics?

The type of pneumatic or rubber tires for a hand truck can directly affect strain on the body. Pneumatic tires reduce vibration and impact that travels up through the hands and arms, while solid rubber tires transfer more feedback into the operator. Over long shifts, the difference can influence fatigue levels and injury risk.

3. Can tires affect damage rates to the products being transported?

Yes — poor tire choice can increase breakage or scuffing. When selecting pneumatic or rubber tires for a hand truck, consider cargo sensitivity. Pneumatic cushioning protects fragile items better, whereas solid tires keep heavy, stacked loads stable but don’t absorb vibration when surfaces are rough.

4. How do I know when it’s time to replace my hand truck tires instead of maintaining them?

If you’re constantly repairing flats or noticing uneven wear, evaluating pneumatic or rubber tires for hand truck options can reveal whether a switch is more economical. Frequent downtime means solid rubber could reduce interruptions, while repeated indoor wheel failures may indicate the wrong tread or load rating.

5. Do tire choices impact floor damage or noise levels in sensitive environments?

Absolutely. When choosing pneumatic or rubber tires for a hand truck, performance in noise-controlled areas like hospitals, schools, or retail spaces, pneumatic tires reduce sound and floor vibration significantly. Solid rubber is durable but can create higher noise output on certain surfaces, which matters in public spaces or after-hours operations.