When was the last time you thought about the small wheels under your wheelchair? For many, they’re out of mind until a push feels rough, steering gets shaky, or rims get stuck on floor cracks. But those front wheels, especially rubber wheelchair casters, shape every turn, bump, and glide you make. They affect comfort, control, safety, and even how far you go before tiring out.

Let’s break down what to pay attention to, how to pick the right casters, and the signs it’s time for an upgrade.

At a Glance:

Mobility Starts at the Casters: Rubber wheelchair casters shape how smooth, comfortable, and controlled everyday movement feels.

Fit to Real Use: Choose casters based on surfaces, vibration sensitivity, weight needs, and daily travel patterns — not default factory sizing.

Different Types, Different Results: Solid, soft-roll, pneumatic, and specialty casters each solve specific mobility challenges.

Performance Signals Matter: Hard steering, wobble, vibration, or noise are early signs that casters are limiting independence.

Smart Upgrades Pay Off: The right replacement reduces strain, restores confidence, and improves everyday comfort and efficiency.

Rubber Casters: What They Are and Why They Matter

Rubber wheelchair casters are the small front wheels built with a soft-tread rubber surface designed to absorb vibration and provide smooth, controlled steering. They play a major role in how easily a wheelchair turns, how comfortably it rolls over bumps or transitions, and how much effort is required to push or propel it.

The right match depends on how and where the wheelchair is used, the weight it carries, and the surfaces it rolls across.

That’s where selection criteria matter most:

What to Consider | What It Means | Why It Matters |

Wheel Size (Diameter & Width) | How big or wide the caster is | Bigger wheels roll easier over bumps and thresholds; width improves stability during turns |

Rubber Softness / Tread Type | How firm or cushioned the wheel feels | Softer tread absorbs vibration and reduces discomfort from rough surfaces |

Bearing Quality | Smoothness of internal movement | Less push effort, easier steering, less strain on shoulders/wrists |

User Weight Capacity | Total load the caster supports | Prevents wobble, shimmy, and sudden steering drift under real use |

Floor / Terrain Fit | Where is the wheelchair used most | Indoor tiles vs outdoor paths vs mixed surfaces need different traction |

Chair Compatibility | How the caster fits the frame and fork | Avoids changes to seat height, geometry, or turning control |

Once you understand what to look for, the next step is choosing the type of rubber caster that fits real-world use.

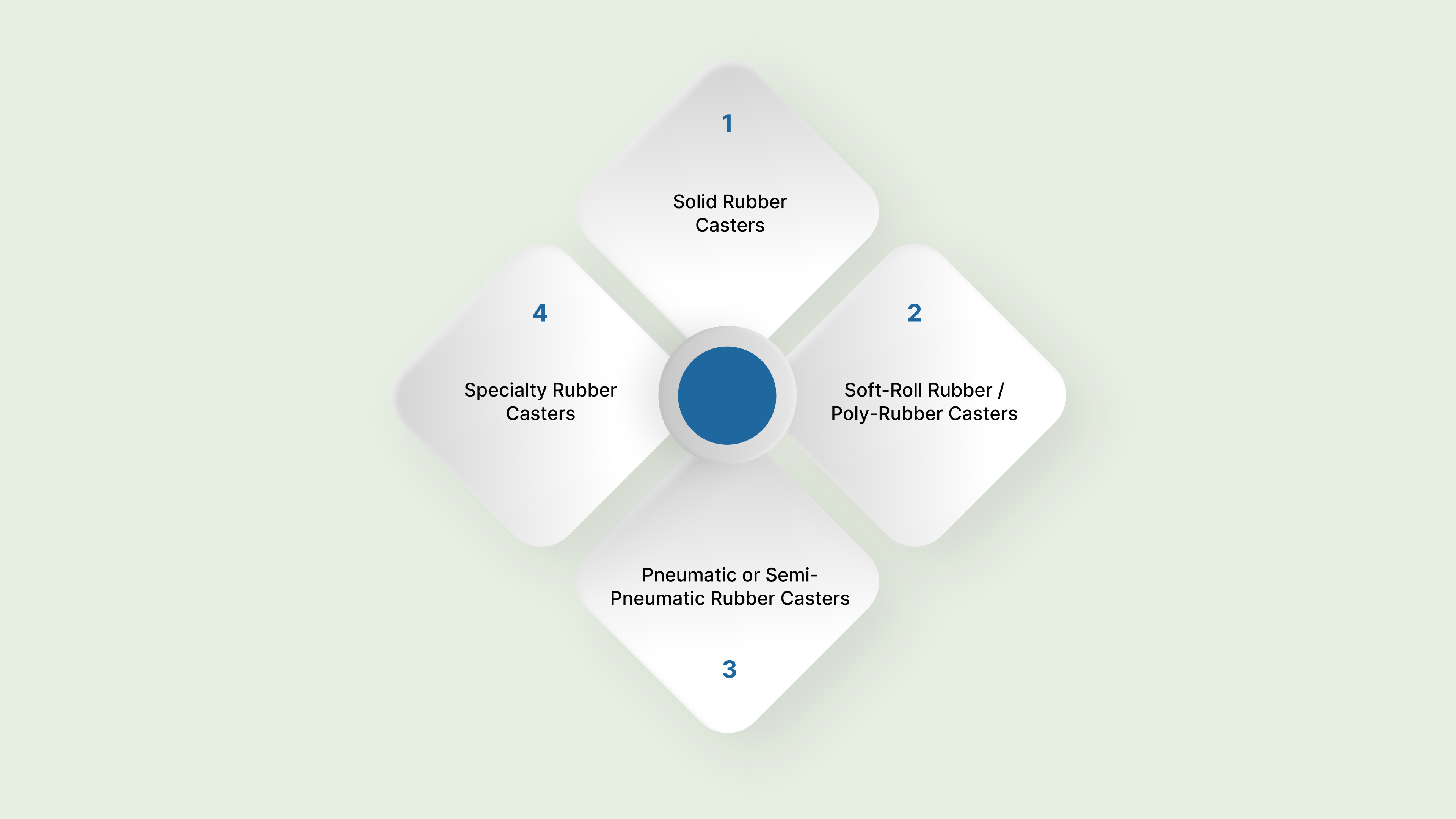

Types of Rubber Wheelchair Casters

Rubber wheelchair casters aren’t one-size-fits-all. Different designs handle movement, comfort, vibration, and terrain in different ways. Choosing the right type depends on where the wheelchair is used, how much mobility support the user needs, and the surfaces most frequently traveled.

Here are the main options and when they make the biggest difference:

1. Solid Rubber Casters

Solid rubber casters are firm, durable wheels made from dense rubber compounds designed for consistent performance on smooth indoor surfaces.

Best suited for

Hospitals, clinics, rehab centers, and indoor mobility environments

Users who need predictable steering and low-maintenance wheels

Operational advantages

Reliable handling on smooth floors — easy to control in tight hallways and clinical spaces

Low rolling resistance — requires less push effort for everyday mobility

Quiet and floor-friendly — ideal for polished, tiled, or vinyl flooring

Low maintenance — no air pressure to monitor and fewer wear issues

Considerations/limitations

Not ideal for rough outdoor terrain or uneven surfaces; can feel harsh over cracks or gravel

Less shock absorption than softer or pneumatic options

Ideal for

Daily indoor wheelchair use

Caregiver-pushed wheelchairs

Facilities prioritizing smooth, clean flooring and quiet operation

2. Soft-Roll Rubber / Poly-Rubber Casters

Soft-roll rubber or poly-rubber casters use a cushioned tread layer designed to absorb vibration and provide a smoother ride on mixed or imperfect surfaces.

Best suited for

Indoor/outdoor mobility paths (transitions like door thresholds, ramps, sidewalk joints)

Users sensitive to vibration or discomfort

Operational advantages

Smoother, cushioned ride — reduces jolting when rolling over everyday surface changes

Better grip and control — improved traction on slightly slick floors or wet areas

Reduced vibration transfer — helpful for users with pain, spasticity, or joint sensitivity

Quieter operation — less wheel chatter on hard surfaces

Considerations/limitations

Can wear faster on rough outdoor surfaces or debris-heavy paths

Slightly higher rolling resistance compared to solid rubber

Ideal for

Active users moving across mixed indoor/outdoor environments

Rehab and therapy settings focused on comfort and joint protection

Wheelchair users who travel frequently through public spaces, ramps, or uneven flooring

3. Pneumatic or Semi-Pneumatic Rubber Casters

Pneumatic and semi-pneumatic rubber casters use air-filled or air-enhanced tires that offer maximum shock absorption and cushioning for wheelchairs. They’re built to handle rough terrain, bumps, and uneven surfaces while preserving ride comfort.

Best suited for

Outdoor use — sidewalks, driveways, curbs, uneven paths

Users frequently transition between indoor floors and rough outdoor terrain

Situations where comfort and impact absorption matter more than compact indoor maneuverability

Operational advantages

Excellent shock absorption and vibration damping — smooth movement over cracks, bumps, and uneven surfaces

Improved obstacle clearance — handles curbs, small steps, thresholds without jarring the user

Enhanced comfort and reduced fatigue — softer ride reduces stress on joints and spine, ideal for long-distance mobility or outdoor use

Better suitability for mixed terrain — indoor comfort with outdoor versatility in one setup

Considerations/limitations

Requires occasional maintenance (checking air pressure or tire condition)

A larger diameter may slightly affect the turning radius and indoor maneuverability

Slightly more rolling effort compared to solid or soft-rubber casters on flat surfaces

Ideal for

Users who spend significant time outdoors or move between indoor and outdoor spaces

Wheelchairs for daily community use, errands, or recreational use

Those prioritizing comfort and a smooth ride over compactness in indoor settings

4. Specialty Rubber Casters (Suspension, Anti-Shimmy, Bariatric, Non-Marking, etc.)

Specialty rubber casters are engineered for specific performance needs that standard or pneumatic wheels can’t solve, such as vibration isolation, stability at higher speeds, handling heavier users, or preventing caster flutter (shimmy).

Best suited for

Users who experience steering wobble or instability at speed

Bariatric wheelchairs or heavier load requirements

Chairs used in environments with vibration sensitivity (rehab therapy, neurological conditions)

Facilities that need non-marking wheels for premium flooring

Operational advantages

Anti-shimmy control — prevents caster flutter during quick turns or when moving fast.

Suspension or shock-absorbing options — isolates impact for smoother motion over uneven surfaces.

High-stability design — maintains tracking direction with less effort and fewer steering corrections.

Non-marking rubber tread — protects polished floors, hospitals, and rehab clinics from streaks or scuffs.

Supports higher weight limits — provides safer mobility for bariatric needs without compromising handling.

Considerations/limitations

Higher cost compared to standard casters

Requires correct pairing with chair geometry and fork design for best performance

Ideal for

Bariatric users or power-assist setups

Performance-oriented manual wheelchair users

Healthcare and rehab environments prioritizing precision, comfort, and floor protection

Users who routinely experience wobble or vibration and need higher stability and control

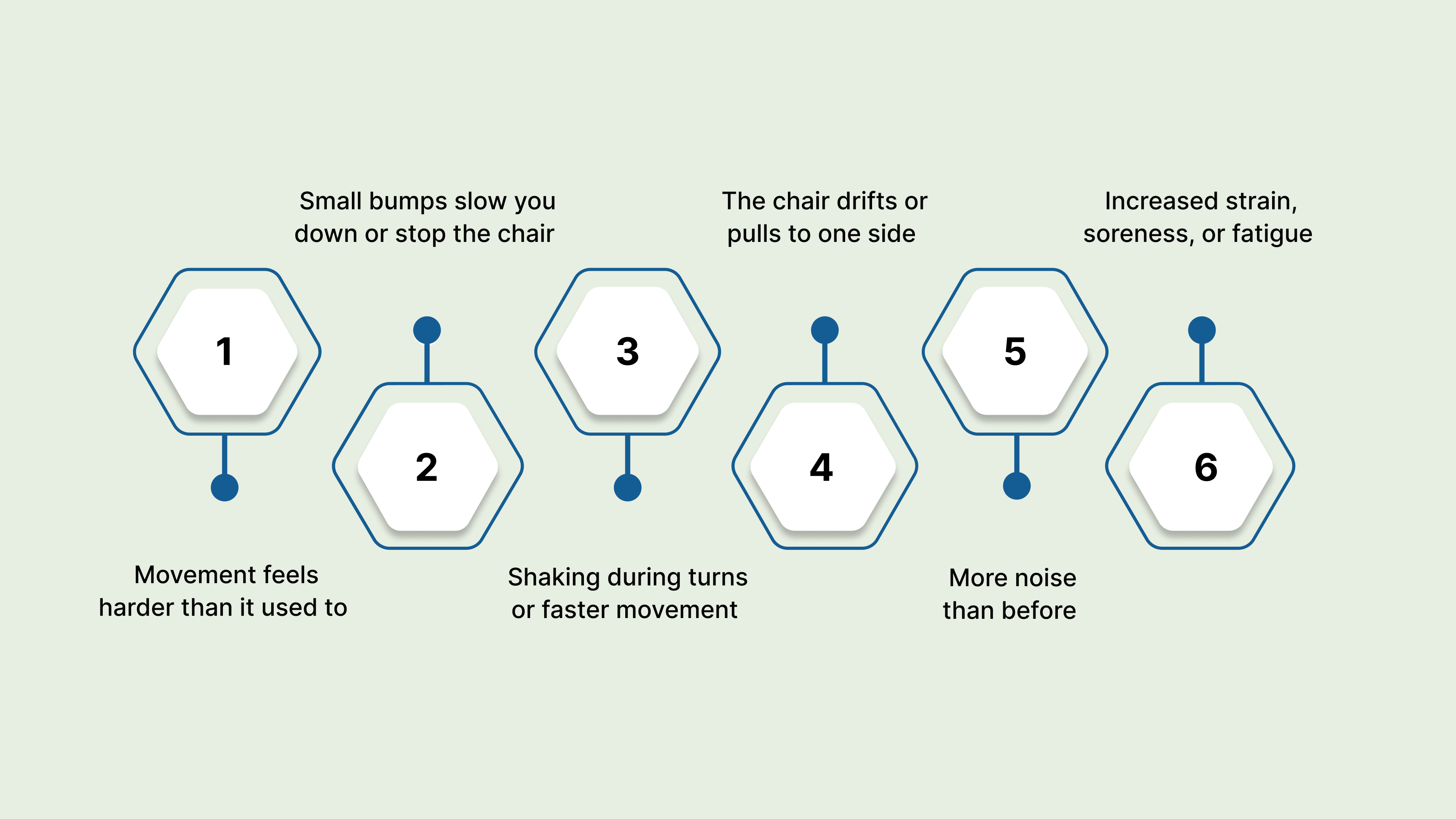

Even the best casters don’t last forever. Performance changes gradually, and most users notice the effects long before the wheels visibly wear out. If movement feels different from how it used to, the casters are likely telling you something.

When to Replace or Upgrade Rubber Wheelchair Casters

Rubber casters don’t announce their end-of-life with dramatic failures. The real clue is when mobility efficiency starts to slip, when everyday movement takes more effort than yesterday, and small obstacles suddenly feel bigger.

Here are the signals to watch for:

Movement feels harder than it used to

When pushing across a smooth floor starts feeling like climbing a hill, the casters are losing rolling efficiency, often from worn bearings or tread compression.

Small bumps slow you down or stop the chair

If door thresholds or tile edges that were once effortless now cause sudden jolts or require force to get over, shock absorption is breaking down.

Wobbling or shaking during turns or faster movement

A front-end “shimmy” or vibration when turning or rolling downhill means stability is no longer consistent, a common sign of caster wear.

The chair drifts or pulls to one side

When keeping a straight path requires constant steering correction, it often points to uneven tread wear or bearing alignment issues.

More noise than before

Clicking, rattling, grinding, or harsh rolling sounds indicate internal components are wearing out, even if the wheel surface still looks fine.

Increased strain, soreness, or fatigue

If short trips now leave your shoulders, wrists, or back more tired than usual, the casters are forcing you to work harder than necessary.

When those signs start showing up, the next step is choosing replacements that actually solve the problem rather than repeating it. A quick fitment check helps ensure the new casters match the way the wheelchair is used and fit correctly without changing handling or stability.

Here’s what to review before ordering:

What to Check | What It Means | Why It Matters |

Wheel Diameter & Width | Measure existing caster size | Maintains seat height, stability, and turning control |

Fork Clearance & Mounting Type | Check fork spacing and bolt/stem fit | Prevents rubbing, alignment issues, or installation problems |

Weight Capacity | User weight + accessories carried | Stops wobble or shimmy under real use, not just rated load |

Tread Softness / Material | Firm vs soft rubber, depending on terrain | Balances comfort, vibration reduction, and rolling effort |

Bearing Quality | Smoothness and type of bearing | Reduces push force and fatigue, improves steering |

Primary Use Environment | Indoor, outdoor, or mixed terrain | Ensures traction, durability, and obstacle clearance |

Maintenance Preference | Solid vs pneumatic upkeep | Avoids mismatched care expectations and premature failure |

Replace in Pairs | Swap both front casters together | Keeps tracking direction consistent and prevents uneven movement |

When mobility, comfort, and reliability are on the line, having a partner who understands real-world use, not just product specs, makes the process easier and safer.

How Humphries Casters & Supplies Can Help

Choosing the right rubber wheelchair casters is only half the equation; the bigger challenge is finding a supplier who understands real-world mobility needs, not just catalog numbers. That’s why working with a knowledgeable partner matters, especially when precision and reliability directly affect someone’s daily life.

Humphries Casters supports buyers, caregivers, facilities, and rehab professionals with guidance rooted in experience, not guesswork.

What You Can Expect From Humphries Casters

Material-specific recommendations based on load type, terrain, speed cycles, sanitation requirements, and usage frequency.

Extensive wheel selection, including polyurethane, urethane, and specialty compounds engineered for harsh or regulated environments.

OEM-equivalent and custom-manufactured options to ensure compatibility and eliminate modification delays.

Bulk and scheduled purchasing programs for multi-location facilities, warehouses, and high-cycle operations.

Proven expertise across industries, including hospitals, food-processing, distribution centers, assembly lines, and transport logistics.

Reliable sourcing partnerships with access to hundreds of manufacturing facilities for rapid fulfillment and application testing.

Humphries Casters becomes a real ally when you need reliable wheelchair or caster-wheel solutions, not just another parts vendor.

Wrapping Up

Rubber wheelchair casters may look small, but they influence mobility more than most users realize. When rolling starts feeling harder, bumpier, or less predictable, it’s often the casters, not strength or skill, that are holding you back.

Upgrading isn’t about replacing a worn part; it’s about protecting independence and reducing strain so movement feels natural again.

If your wheelchair isn’t moving the way it should, that’s a signal worth listening to.

Need help choosing the right setup? Reach out to us, and we’ll help you find the best fit for real-world use.

FAQs

1. How often should rubber wheelchair casters be replaced?

There’s no universal timeline; replacement depends on usage frequency, terrain, and user weight. If movement feels harder, steering becomes unpredictable, or vibration increases, it’s time to evaluate replacements rather than waiting for visible damage.

2. Do different caster types change how a wheelchair handles corners and tight spaces?

Yes. Wheel diameter, tread softness, and bearing smoothness all affect turning response. A caster that’s too firm, too small, or worn can make tight turns feel jerky or require extra force.

3. Can changing caster size affect seat height or stability?

Absolutely. A larger caster can raise the seat and shift the chair’s center of gravity, affecting balance and footrest clearance. That’s why measuring fitment before ordering is essential.

4. Why do casters start to wobble or shimmy at higher speeds?

Shimmy is often caused by worn bearings, uneven tread wear, or casters that no longer match load and speed conditions. Upgrading to anti-shimmy or higher-stability casters usually resolves it.

5. Are softer rubber casters always more comfortable?

Not always. Softer casters improve shock absorption, but they can wear faster outdoors or feel sluggish indoors. The best choice depends on where the wheelchair is used most.