Choosing the right wheels for your equipment shouldn’t feel confusing or overwhelming. When you’re comparing nylon vs polyurethane wheels, the decision comes down to how and where you use them.

Nylon wheels are known for strength, rigidity, and impressive load-carrying ability, great when you need raw power and durability. Polyurethane wheels, on the other hand, offer quiet, cushioned rolling with better floor protection and more operator comfort.

So if you’re wondering which option performs better, lasts longer, or fits your environment, you’re in the right place. Let’s dive in and take a quick look at both material types.

Key Takeaways:

Material Purpose: Nylon vs polyurethane wheels serve different needs; nylon prioritizes strength and speed, while polyurethane focuses on comfort and floor protection.

Performance Fit: Nylon excels in heavy-load, high-speed industrial environments; polyurethane performs best in mixed routes and noise-sensitive or customer-facing spaces.

Operator Impact: Nylon can increase vibration and noise, while polyurethane reduces fatigue and minimizes sound during long shifts.

Surface Consideration: Nylon requires predictable hard floors; polyurethane adapts to variable surfaces, obstacles, and damp conditions.

Cost Efficiency: The right choice between nylon vs polyurethane wheels lowers downtime, maintenance, and floor repair costs over time.

Decision Rule: Choose based on workflow style and environment, not by price alone, for the best long-term results.

A Quick Look at Both Wheel Types

Before you compare performance and applications, you need a clear understanding of what each wheel material is designed to do. This section gives you a straightforward snapshot of nylon vs polyurethane wheels: how they’re built, how they behave under load, and the environments they’re best suited for.

Let’s start with nylon wheels.

What Are Nylon Wheels?

Nylon wheels are made from a tough, rigid thermoplastic engineered for strength, high load capacity, and long service life in demanding environments. You’ll typically use them when you need wheels that can handle heavy weights without flexing or deforming.

Their hard structure allows them to roll efficiently with minimal friction, making them ideal for fast-moving industrial operations that prioritize durability over cushioning or noise reduction.

Key Traits

High load-bearing capacity — supports heavy equipment and stacked loads without compressing.

Low rolling resistance — requires less effort to start and maintain movement on smooth, hard surfaces.

Impact and wear resilience — tolerates aggressive industrial use and rough handling without cracking.

Heat resistance — performs reliably in high-temperature processes and manufacturing environments.

Low moisture absorption — doesn’t swell or degrade when exposed to water or humidity.

What Are Polyurethane Wheels?

Polyurethane wheels are made from a versatile elastomer designed to provide a balance of durability, flexibility, and floor protection. Unlike harder materials, polyurethane offers a cushioned rolling experience that reduces vibration and protects floors from scratches and wear.

You’ll typically choose polyurethane wheels when operator comfort, noise reduction, and smoother movement matter just as much as strength and reliability.

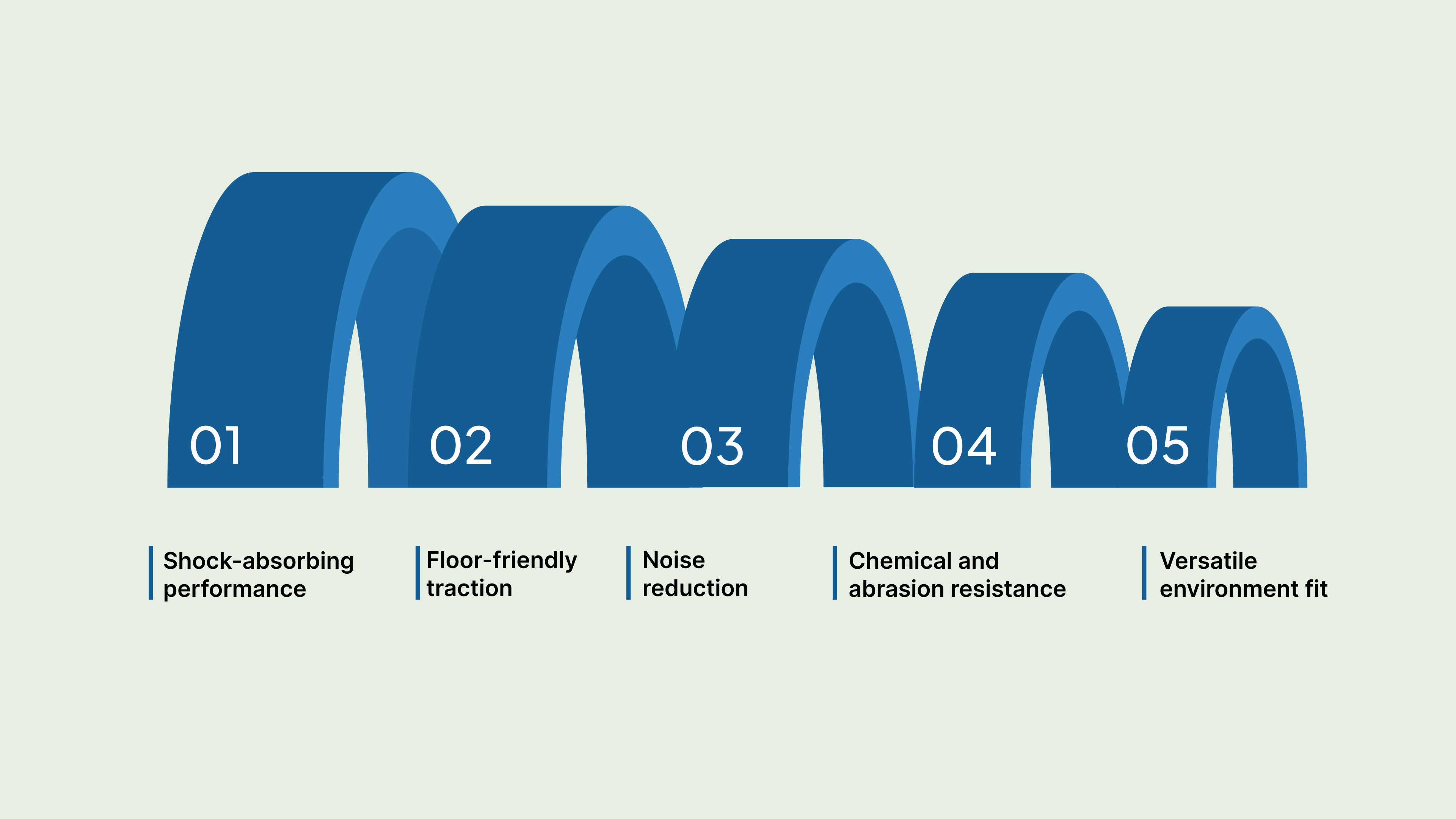

Key Traits

Shock-absorbing performance — cushions vibration to protect both loads and operators.

Floor-friendly traction — grips surfaces without marking or scratching, ideal for polished or coated floors.

Noise reduction — significantly quieter than hard wheel materials in busy or customer-facing environments.

Chemical and abrasion resistance — withstands contact with solvents, oils, and heavy friction.

Versatile environment fit — performs well in warehouses, production floors, clean spaces, and mixed-route applications.

Now that you understand the basic characteristics of both materials, it’s time to compare how they perform in real working conditions.

Nylon vs Polyurethane Wheels: Key Differences

When you compare nylon vs polyurethane wheels, the real difference comes down to how each material performs under pressure and in different working environments. Depending on the equipment you’re moving and the surfaces you work on, choosing the right material can dramatically affect efficiency, safety, and long-term maintenance costs.

The table below breaks down the most important performance differences:

Decision Factor | Nylon Wheels | Polyurethane Wheels |

Force Required to Move | You push with less effort on smooth, hard floors due to very low rolling resistance. | You apply slightly more force, but gain better control on mixed or uneven surfaces. |

Operator Comfort & Ergonomics | You feel more vibration and noise transfer through equipment during movement. | You experience quieter rolling and reduced vibration, improving comfort on long routes. |

Floor Impact & Protection | Can damage or mark delicate surfaces, especially under heavy loads. | Protects floors, reduces scuffing, and helps maintain surface quality in customer-facing spaces. |

Shock & Impact Handling | Performs best on firm floors with minimal debris or transitions. | Handles bumps, expansion joints, and irregular surfaces without load disturbance. |

Performance on Wet or Slippery Floors | Can lose traction and become louder or harsher when wet. | Maintains better grip and smoother roll through damp or variable conditions. |

Noise Levels in Operation | Produces higher noise output, noticeable in quiet environments. | Runs significantly quieter — suitable for hospitals, retail, schools, and night-shift operations. |

Best Fit for Workflow Style | High-speed, heavy-load, straight-path industrial movement. | Mixed-route, comfort-focused, or customer-facing workflows needing smooth handling. |

The right choice between nylon vs polyurethane wheels comes down to your floor conditions, load demands, and how you need the equipment to perform day-to-day.

How to Choose the Right Wheel Material?

When deciding between nylon vs polyurethane wheels, you need to focus on how your equipment is used, not just the material specifications. By evaluating real working conditions, you can select the wheel material that delivers the best performance and lowest long-term cost.

Use the guidance below to pinpoint which option fits your application.

Decision Priority | Choose Nylon Wheels If… | Choose Polyurethane Wheels If… |

Operational Pressure | You need maximum throughput and rigid performance under time-critical workflows. | You need smoother handling that maintains consistency across variable routes and floor conditions. |

Risk & Downtime Impact | A wheel failure would stop production or disrupt automation, and reliability is non-negotiable. | Secondary risks like floor damage, noise control, or ergonomic strain carry a higher cost than wheel durability alone. |

Human vs Machine Use | Equipment is powered or automated, where mechanical efficiency matters more than comfort. | Equipment is manually pushed or pulled, and reducing operator fatigue drives productivity. |

Environmental Volatility | You operate in controlled, stable environments with predictable surfaces and temperatures. | You work across changing surfaces, temperature shifts, moisture, or debris that demand flexibility. |

Scaling & Standardization | You want uniform specifications for large fleets or repeat industrial cycles. | You’re planning for future-proof versatility across diverse facility zones or customer-facing spaces. |

With a clear understanding of how each wheel material performs under real operational pressures, the next step is choosing a supplier who can help you match the right solution.

Where Humphries Casters Comes In

Selecting the right wheel material is simpler when you have support from a supplier who understands how equipment performs in real-world environments, not just on spec sheets. Humphries Casters brings deep application knowledge and a broad product network to help you identify the best wheel solution for your operational demands.

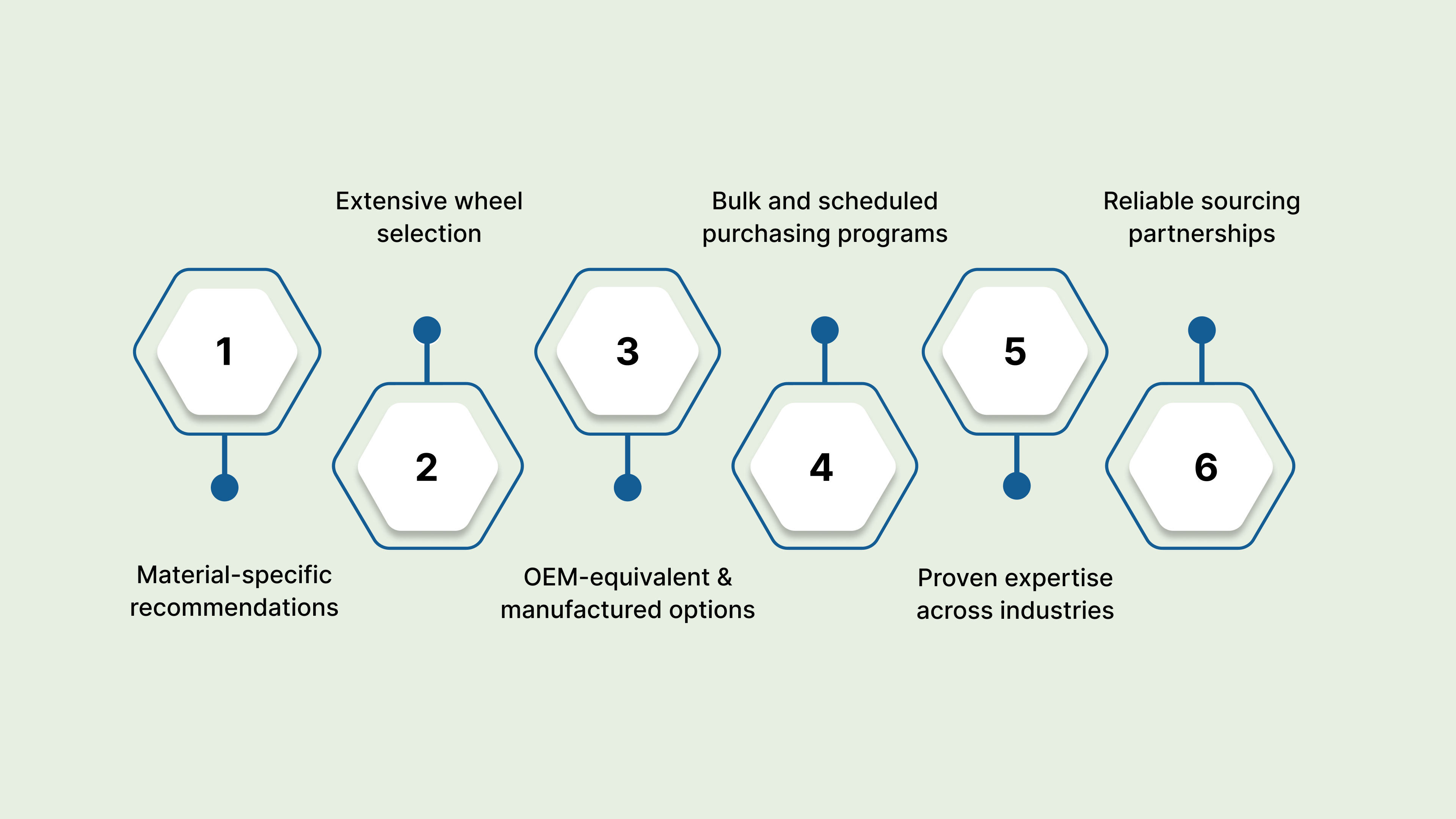

What You Can Expect From Humphries Casters

Material-specific recommendations based on load type, terrain, speed cycles, sanitation requirements, and usage frequency.

Extensive wheel selection, including polyurethane, urethane, and specialty compounds engineered for harsh or regulated environments.

OEM-equivalent and custom-manufactured options to ensure compatibility and eliminate modification delays.

Bulk and scheduled purchasing programs for multi-location facilities, warehouses, and high-cycle operations.

Proven expertise across industries, including hospitals, food-processing, distribution centers, assembly lines, and transport logistics.

Reliable sourcing partnerships with access to hundreds of manufacturing facilities for rapid fulfillment and application testing.

From equipment upgrades to resolving persistent wheel issues, Humphries Casters helps you make confident decisions that improve performance and long-term efficiency.

Conclusion

The difference between nylon vs polyurethane wheels affects not just how equipment moves, but how efficiently your team works. The smartest decision comes from understanding what matters most in your environment: speed and rigidity, or comfort and versatility.

If you want help determining which wheel material is the best fit for your space, equipment, and workflow goals, Humphries Casters is here to guide you.

Have questions or need help choosing between nylon vs polyurethane wheels? Reach out to us for expert support tailored to your operation.

FAQs

1. Can switching between nylon vs polyurethane wheels change how much force is required to move equipment?

Yes. When comparing nylon vs polyurethane wheels, nylon typically requires less force on smooth floors, which speeds up movement in high-throughput environments. Polyurethane may require slightly more initial force, but reduces strain over longer distances because it absorbs vibration and offers better grip.

2. Do nylon vs polyurethane wheels perform differently on automated equipment or robotics systems?

They do. In nylon vs polyurethane wheels applications involving robotics or conveyors, nylon tends to provide more consistent rolling at high speeds. Polyurethane performs better when equipment needs controlled acceleration, softer contact, or lower noise output.

3. Are nylon vs polyurethane wheels affected differently by chemicals or cleaning agents?

Yes. Polyurethane handles exposure to oils, solvents, and sanitizing chemicals better than nylon in washdown or food-processing environments. Nylon is more sensitive to certain chemicals, so review exposure conditions before choosing nylon vs polyurethane wheels.

4. Which wheel material is safer for environments with temperature fluctuations?

Polyurethane generally remains more stable and flexible in varying temperatures, including cold storage. Nylon can become brittle in very low temperatures. If temperature swings are common, nylon vs polyurethane wheels will perform differently, and polyurethane is often the safer choice.

5. Can the wrong choice between nylon vs polyurethane wheels increase maintenance costs?

Absolutely. Selecting the wrong material can lead to faster wear, floor damage, noise issues, or operator fatigue. When deciding between nylon vs polyurethane wheels, consider the long-term cost of downtime, floor repairs, and employee ergonomics in addition to the initial price.

0