You order replacement caster wheels based on a simple description: "standard 4-inch casters." Six weeks later, they arrive. Installation fails. The stem is too wide. The mounting holes don't align. You're stuck with unusable wheels and a broken timeline.

This happens because you assumed caster wheels are interchangeable. They're not. Caster wheels are highly specific to equipment design, load requirements, environment, and operational needs. One wheel does not fit all applications.

Treating casters as universal components causes safety problems, floor damage, and expensive downtime. Getting specifications right prevents these issues before they start.

In this guide, you'll learn why caster wheels aren't interchangeable, what makes each one specific, and how to specify the right one for your operation.

At A Glance:

Caster wheels are not universal; they are specialized assemblies designed for specific loads, speeds, and environmental conditions.

The most frequent cause of installation failure is mismatching the exact plate bolt pattern or the stem's critical diameter and thread pitch.

Always calculate the dynamic load capacity by dividing the total weight by three, not four, to build in the necessary safety factor for uneven floors.

The wheel material must align precisely with the operating environment (e.g., cold storage, chemicals) to prevent premature brittleness and floor damage.

Even slight variations in overall caster height will destabilize the equipment, causing uneven load distribution and rapid component overload.

Understanding Caster Wheels And Types

Caster wheels are rotating components that enable equipment to move across floors. They consist of a wheel (rotating part), a swivel or fixed mount, and a stem or mounting plate (attaches to equipment).

Casters serve three functions: distribute weight evenly, reduce movement force, and adapt to different floor types. The wheel itself is engineered for specific purposes. Diameter, width, material, bearing type, and load rating all vary based on intended application.

Basic Types of Casters Wheels

Swivel caster wheels: Rotate side to side for flexible movement in any direction. Common in warehouses and retail environments where tight turning is necessary.

Rigid caster wheels: Move straight only, providing stability. Used on equipment that travels predictable paths like conveyor systems or assembly lines.

Locking caster wheels: Include brakes or swivel locks for stationary equipment. Essential in hospitals and food service, where equipment must stay in place.

Heavy-duty caster wheels: Built for extreme loads (500+ lbs per caster). Used in manufacturing plants and distribution centers handling pallets.

Now that the fundamentals are clear, we can definitively address the core industry misconception. We will confirm why the universal caster does not exist.

Are Caster Wheels Universal?

No. Caster wheels are not universal. Mounting types, stem dimensions, load capacities, materials, and brake systems differ across applications. Assuming interchangeability results in installation failures, poor performance, and safety hazards. One-size-fits-all doesn't exist in caster specification.

The non-universality stems from many highly specific design requirements. You must understand the critical variables that define a caster's specialization.

Explore our extensive caster wheel catalogue to see the range of specialized options available for your industry.

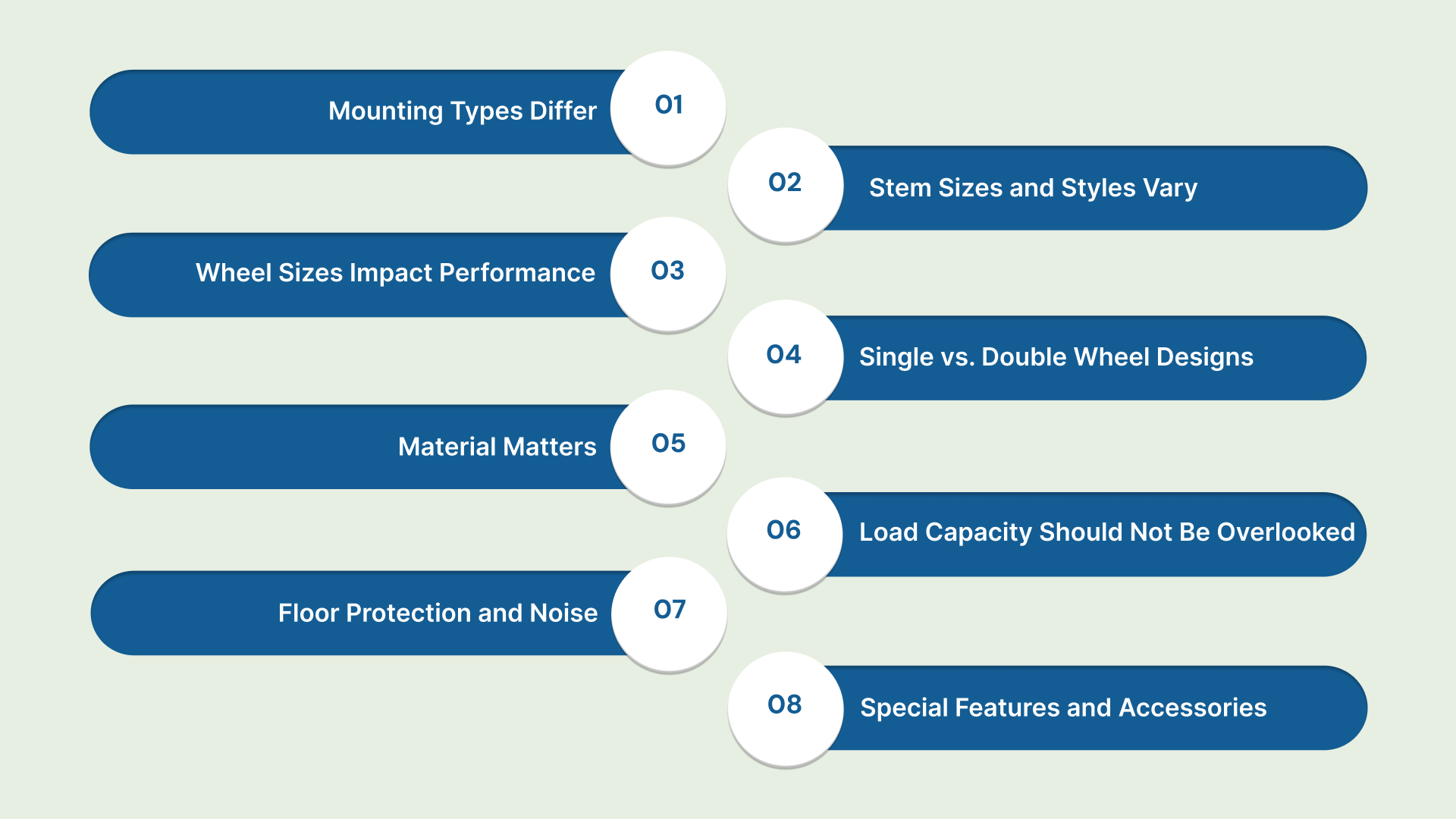

8 Factors That Make Casters Non-Universal

The vast diversity in applications, from bakery ovens and sub-zero freezers to sensitive medical instruments, demands specialized caster designs. You must consider these eight variables to ensure reliability and safety:

1. Mounting Types Differ

Mounting systems attach casters to equipment. Three primary types exist, and they are not interchangeable.

Plate mount: Flat metal plate with bolt holes. Requires a matching bolt hole pattern on your equipment. Bolt spacing varies (2x2 inches, 3x4 inches, etc.). A wrong pattern means no installation.

Threaded stem: Vertical post with threads on the end. Your equipment has a threaded hole. Stem diameter must match exactly (1/2 inch, 5/8 inch, 3/4 inch). The wrong diameter won't fit your hole.

Rivet mount: Caster riveted permanently to the equipment. Cannot be replaced with bolt-on options without removing rivets. Rare in modern equipment, but it still exists.

2. Stem Sizes and Styles Vary

Stems connect wheels to equipment. Mismatches prevent installation.

Stem height matters: Height determines caster position above the equipment. Wrong height changes equipment clearance and stability. A 4-inch stem for a 5-inch mounting creates a 1-inch height difference.

Stem diameter affects fit: Too small, stem rattles. Too large, won't fit the hole at all. Sizes include 1/2 inch, 5/8 inch, and 3/4 inch.

Thread specifications differ: Threaded stems have different pitches (distance between threads). Wrong pitch damages equipment threads, making future replacements difficult.

3. Wheel Sizes Impact Performance

Caster wheel diameter directly affects load capacity and rolling characteristics.

Larger wheels support more weight: 6-inch wheels handle heavier loads than 4-inch wheels. Size determines bearing capacity and weight distribution.

Wrong size causes premature failure: Undersized wheels flatten under load. Bearings fail quickly. Equipment becomes difficult to move.

Width affects stability: Wider wheels are more stable. Narrower wheels maneuver better. Using the wrong width affects how the equipment sits and rolls.

4. Single vs. Double Wheel Designs

Some casters have one wheel. Others have two wheels side by side. Not interchangeable.

Single wheels: One wheel per assembly. Standard for 90% of applications. Each caster carries its share of the load.

Double wheels: Two wheels on one assembly. For extreme loads. Each wheel carries less weight individually. Wider, affecting the turning space.

Mixing single and double wheels on the same equipment creates unpredictable handling and instability.

5. Material Matters

Wheel material determines performance in different environments. No single material excels everywhere.

Polyurethane: Durable, handles most floor types. Works on hard, dry floors in warehouses. Cost-effective. Fails in cold storage (becomes brittle below 32°F).

Rubber: Excellent grip on polished floors. Quiet operation. Used in hospitals and retail. Wears faster than polyurethane in heavy use.

Nylon: Lightweight, inexpensive. Works on smooth surfaces. Light-duty only. Not suitable for heavy loads or wet environments.

Phenolic: Maintains rigidity in freezing conditions. Resists moisture. Used in cold storage and food facilities. Harder can damage soft floors.

Looking for a custom solution for high-heat or sub-zero environments? Contact our team about specialized material recommendations, and we will custom-manufacture a caster wheel to your specifications.

6. Load Capacity Should Not Be Overlooked

Casters have maximum weight ratings. Ratings are specific to design and intended use. Exceeding capacity causes failure and safety hazards.

Calculate load per caster: Weigh equipment plus load. Divide by the number of casters (usually 4). The result is the load per caster. Must be below rated capacity.

Example: Cart weighs 150 lbs empty. Load is 800 lbs. Total: 950 lbs. With 4 casters: 950 ÷ 4 = 237.5 lbs per caster. Need casters rated for at least 250+ lbs.

Exceeding capacity causes: Wheels flatten. Bearings fail. Casters stop rolling smoothly. Equipment becomes unstable. Safety hazard for workers.

7. Floor Protection and Noise

Different wheels affect floors and sound levels differently.

Non-marking wheels: Use softer materials. Don't leave marks on polished floors. Essential in hospitals, retail, and upscale facilities. Trade-off: wear faster (8–12 months vs. 18–24 months).

Noise levels vary by material: Hard wheels (nylon, phenolic) are loud. Soft wheels (rubber) are quiet. In hospitals, noise matters. Loud casters disturb patients and staff.

Material affects floor durability: Hard wheels can damage soft floors. Soft wheels are gentler. The wrong choice damages floors requiring expensive refinishing.

8. Special Features and Accessories

Beyond the basic wheel, casters include features that aren't always compatible.

Brake types: Foot-activated, total-lock, pressure-release brakes. Different holding strengths. The wrong type means carts roll unexpectedly.

Swivel vs. rigid: Swivel casters rotate for flexible movement. Rigid move straight only. Mixing on the same equipment creates unpredictable handling.

Height adjusters: Some include adjustable height or levelers. Application-specific, not interchangeable with standard casters.

Specialized features: Shock absorbers, suspension systems for specialized equipment. Cannot mix with standard casters.

Ignoring these specialized variables often leads directly to common, expensive errors. We will now review the most frequent mistakes made during replacement sizing.

Common Mistakes in Universal Replacement Sizing

Procurement and maintenance teams focused on speed often overlook fundamental specification checks. These errors quickly negate any cost savings and lead to greater long-term maintenance costs and safety incidents.

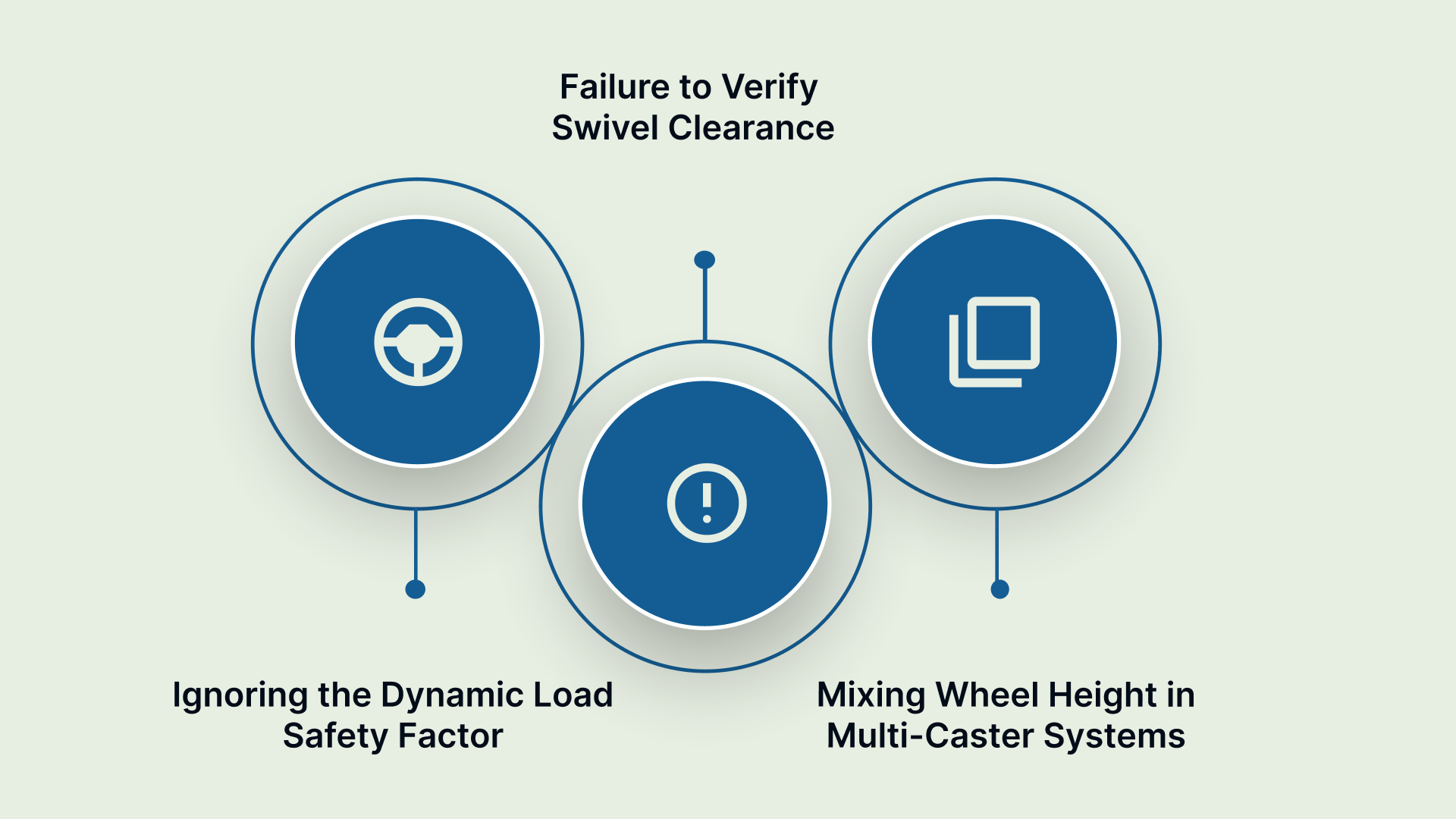

Ignoring the Dynamic Load Safety Factor

When calculating caster capacity, many professionals divide the total weight by four casters. This is dangerous because equipment on uneven floors often rests on only three casters at any time.

The Mistake: Calculating capacity based on four casters (Total Load / 4).

The Correction: Always calculate capacity based on the three-caster principle (Total Load / 3). This builds in the necessary safety margin for real-world application.

Failure to Verify Swivel Clearance

A replacement caster with the correct top plate may still bind or damage the equipment frame. This occurs when the swivel radius is too large for the existing frame cutout.

The Mistake: Only matching the top plate dimensions and bolt holes.

The Correction: Measure the swivel radius (distance from the swivel center to the wheel tread edge). Ensure this radius is equal to or less than the previous caster's clearance.

Mixing Wheel Height in Multi-Caster Systems

Replacing a worn wheel with one that is even a fraction taller or shorter disrupts the cart's level. This creates uneven load distribution, causing one or two casters to carry an overload.

The Mistake: Substituting a slightly different wheel or assembly height.

The Correction: The overall height (distance from the floor to the top of the mounting surface) must match precisely across all casters on the cart or truck.

These errors lead directly to recurring operational problems and preventable safety hazards. Humphries Casters is here to help you move beyond guesswork and failure.

Humphries Casters: Solutions for Complex Mobility Challenges

Operations leaders and safety managers struggle with mismatched casters. Wrong wheels cause downtime, floor damage, and worker injuries. Off-the-shelf options often don't fit demanding environments or load requirements.

Humphries Casters solves this by analyzing your specific environment, load, and needs. We source or manufacture exactly what you need, not what's in a catalog. Our approach ensures reliable mobility designed for productivity and injury reduction.

The Humphries Casters Advantage:

Consultative Approach: We focus on solving operational problems, not just pushing a product.

Custom Engineering: We manufacture non-standard casters and brackets to fit unique OEM and industrial needs.

Unmatched Sourcing: Access to over 400 global factories guarantees the right component for any specialized application.

Ergonomics Focus: Our solutions are designed to reduce push/pull force, minimizing staff fatigue and workplace injuries.

Reliability: We provide parts built for longevity, reducing maintenance cycles and operational downtime.

We offer comprehensive product coverage, enabling your team to consolidate vendors for all mobility and material handling requirements.

Final Thoughts

Caster wheels are not universal. Mounting types differ. Stem dimensions vary. Wheel sizes affect performance. Materials suit different environments. Load ratings are specific to applications. Special features aren't interchangeable.

The solution isn't searching for mythical universal casters. The solution is a precise specification based on your exact equipment, load, environment, and requirements.

Humphries Casters eliminates this guesswork, ensuring that every replacement or custom caster enhances your operational flow and commitment to ergonomics. Contact us today to review your current fleet needs and discover a tailored mobility solution designed to maximize your ROI.

FAQs

Q. Can I use the same replacement caster across all my equipment?

No. Each piece of equipment has specific requirements. Mounting types, stem dimensions, load capacities, and materials differ. Using the same caster across different equipment results in installation failures or poor performance. Always measure your specific equipment first.

Q. What if I can't find a caster matching my exact specifications?

Standard suppliers have limited catalogs. For non-standard specifications, custom manufacturing is the solution. Working with a partner accessing multiple factories worldwide gives you the flexibility to manufacture the exact caster you need.

Q. Why do some of my casters wear out faster than others if they're all the same type?

Uneven wear indicates installation problems, load imbalance, or material incompatibility with your environment. Premature failure in specific wheels suggests the material isn't suited to your conditions. Investigate the root cause instead of replacing them with identical wheels.

Q. Is it safe to mix different caster types on the same equipment?

No. Mixing different materials, sizes, brake types, or swivel configurations creates unpredictable handling and safety risks. All casters on one equipment piece should have the same specifications. Replace entire sets together.

Q. How do I know if a caster rated for 300 lbs works for my 500-lb load?

It won't. Load ratings are engineered limits, not recommendations. Exceeding them causes wheel failure and safety hazards. Calculate your actual load per caster and choose wheels rated 20–30% higher for a safety margin.