Unexpected equipment downtime starts the moment a caster fails on the floor. A worn-out wheel or a frozen bearing immediately halts production or patient care movement. You often resort to costly, high-speed emergency part orders just to restore critical material flow.

This cycle of emergency purchasing happens when you view casters as interchangeable, single units. You overlook the six internal, high-stress components that wear out first. Understanding these individual components is essential for preventing failure and extending equipment life.

This comprehensive guide breaks down the complex anatomy of caster wheel parts into simple, measurable specifications. You will learn exactly how to identify, inspect, and purchase the correct components for maximum operational reliability and staff safety.

At A Glance:

A "caster" is the full assembly, but the "caster wheel" contains six internal parts (tread, core, bearings) that fail first.

Precision bearings are critical because they dramatically reduce the push-pull force required, minimizing staff fatigue and injury risk.

The core and axle are structural components; their strength prevents wheel deformation and hub wobble, which are precursors to catastrophic failure.

The tread material must be matched to the environment (e.g., floor type, temperature) to avoid floor damage and premature wear.

Lubricate the swivel and visually inspect all wheel parts regularly; proactive replacement of worn components cuts costly emergency downtime.

Caster vs. Caster Wheel: What’s the Difference?

The term "caster" refers to the complete assembly attached to the equipment frame. The "caster wheel" is only the rolling component that touches the floor. Understanding this distinction is vital for ordering the correct replacement part.

You must identify whether you need to replace the entire assembly or just the rolling component. Here is a simple breakdown of the main differences between these two parts:

Aspect | Caster | Caster wheel |

Definition | Complete assembly that includes wheel, frame, and mounting hardware. | The round component that rolls on the floor surface. |

Main elements | Wheel, fork/yoke, mounting plate or stem, swivel section, hardware, optional brakes. | Tread, core, hub, bore, bearings, axle contact area. |

Function | Provides mounting, swivel or rigid guidance, and overall mobility for equipment. | Supports load at the floor, manages friction, shock, and noise. |

Replacement scope | Used when you need to change mounting type, height, or swivel/brake design. | Used when mounting is correct, but rolling performance or wear is the issue. |

Typical buyers’ mistake | Order only wheels when the frame or mounting is also worn or incorrect. | Ordering full casters when only the wheel tread or hub needs replacement. |

Understanding this distinction leads directly to core performance metrics. We will now examine how individual parts govern load capacity and safety standards.

How Caster Wheel Parts Affect Load Capacity and Safety

The quality and specification of each internal part directly influence safety, longevity, and ergonomic performance. Component selection is not just about fit but about managing stress and reducing push-pull forces on your employees.

Poorly specified or cheap internal components dramatically increase the risk of injury and floor damage. These three critical areas are directly impacted by the quality and design of your caster components:

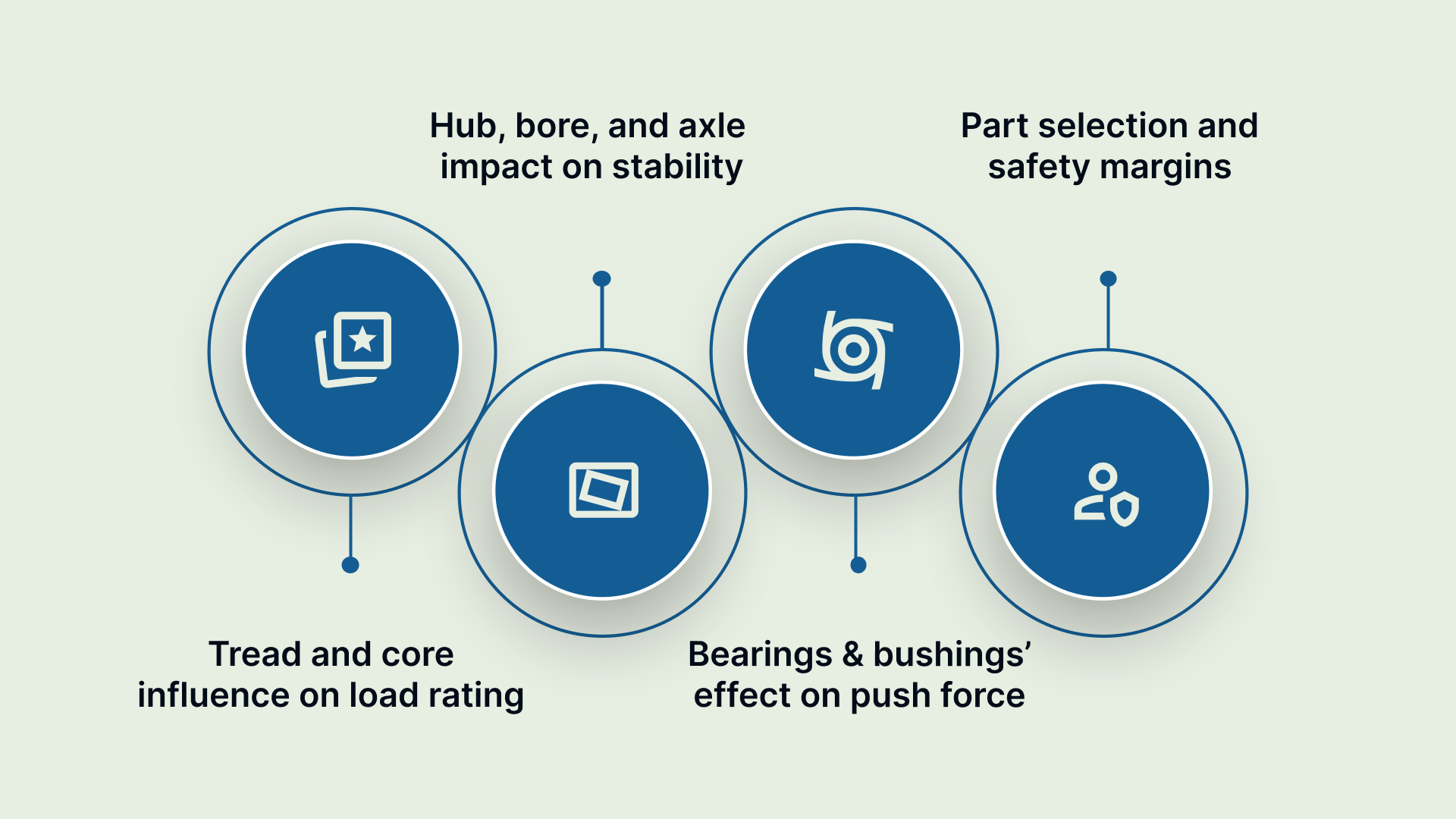

Tread and core influence on load rating

The tread and core share the work of supporting the load. Soft treads spread weight but can deform under heavy loads, while rigid cores resist deformation and protect bearings. A thin tread over a weak core collapses faster, increasing push force and heat buildup under load.

Hub, bore, and axle impact on stability

The hub and bore form the central structure where the axle and bearings sit. Undersized hubs, misaligned bores, or worn axles allow wheel wobble. That wobble increases vibration, noise, and uneven wear, which raises injury risk as operators fight unstable carts.

Bearings and bushings’ effect on push force and control

Bearings and bushings determine how much effort it takes to start and keep a cart rolling. Precision bearings lower push force but may be more sensitive to contamination. Plain bushings are more forgiving but require higher effort and can heat up under continuous use.

Part selection and safety margins

Proper combinations of tread hardness, core strength, bearing configuration, and axle size keep wheels inside their rated conditions. When any part is underspecified, the wheel can flat-spot, crack, or seize, which directly increases the chance of strains, slips, or load shifts.

To truly master specification, you must know the anatomy intimately. The wheel itself relies on six critical components that must be analyzed before ordering.

6 Core Caster Wheel Parts and Their Functions

The wheel itself is an intricate assembly of smaller, high-stress components. When ordering a replacement wheel, you must analyze these six parts. Ordering based on diameter alone overlooks these critical details.

Here is a breakdown of the specific caster wheel parts you must understand for accurate replacement:

Tread

The tread is the outer layer of the wheel assembly, making direct contact with the floor surface. Its composition is critical as it determines floor protection, noise level, and resistance to environmental factors. Treads come in materials like rubber, polyurethane, and nylon, each suited to different conditions.

Functions:

Provides necessary grip and traction for safe movement.

Acts as a cushion between the cart's load and the facility floor.

Determines the level of noise generated during transport.

Resists specific chemicals, water, or high temperatures.

Core

The core is the inner, structural skeleton of the wheel assembly. It provides the rigid support needed to hold the tread and house the bearings. Wheel cores are typically made of durable materials such as polyolefin, cast iron, or aluminum. The core material is chosen based on the required load capacity.

Functions:

Transfers the load from the axle to the tread uniformly.

Maintains the wheel's shape and integrity under heavy compression.

Provides the mounting surface for the wheel bearings.

Hub

The hub is the central section of the wheel core surrounding the axle opening. It is an integral part of the core, designed to accept the bearings or bushings. The hub design ensures the bearings are seated securely and aligned correctly.

Functions:

Provides the precise cavity for bearing or bushing insertion.

Maintains axial stability to prevent side-to-side wobble.

Bearings

Bearings are precision components that allow the wheel to rotate smoothly around the axle with minimal friction. Common types include ball bearings, roller bearings, and plain bearings. Ball bearings offer the best rollability and ergonomic performance for manual pushing.

Functions:

Dramatically reduces rolling resistance and push-pull force.

Facilitates high speeds and sustained movement without overheating.

Carries the load and isolates it from friction-generating surfaces.

Having trouble confirming bearing specifications for your extreme-environment equipment? Contact us to get a custom-manufactured caster wheel suitable for your business needs.

Axle

The axle is a hardened pin or bolt that runs through the wheel's center and connects it to the caster rig's legs. It is a stationary component that supports the entire load while the wheel rotates around it. Axle integrity is vital for maintaining wheel stability.

Functions:

Provides the central pivot point for wheel rotation.

Bears the static and dynamic weight transferred from the rig.

Secures the wheel assembly within the caster legs.

Bushings

Bushings are simple, cylindrical sleeves often used instead of bearings in lower-speed or lighter-duty applications. They are designed to absorb wear and friction. They require little maintenance but increase push-pull resistance compared to ball bearings.

Functions:

Reduces friction between the axle and the hub in low-speed use.

Provides a wear surface that can be easily replaced.

Used in wet or wash-down environments where complex bearings might corrode.

Component knowledge is useless without a proactive strategy. Focus on maintaining these high-stress parts to significantly extend the service life of your fleet.

Best Practices for Maintaining Caster Wheel Parts and Extending Service Life

Proactive maintenance of caster assemblies is a direct strategy to reduce unexpected downtime and cut replacement costs. Ignoring preventative measures forces you into reactive, expensive purchasing cycles.

A disciplined inspection schedule extends the service life of even high-stress components. These essential actions help you maximize the return on investment for your mobility equipment:

Build a regular inspection schedule

Inspect caster wheels on high-use equipment at set intervals. Look for cracks, flat spots, tread separation, hub damage, and loose axles. More frequent checks are useful for heavy loads, long travel distances, or harsh floors.

Keep wheels clean and free from debris

Dirt, string, film, and metal chips can pack around hubs and treads. This increases rolling resistance and can damage bearings. Cleaning wheels with mild detergent and removing wrapped debris helps them roll smoothly.

Lubricate moving interfaces correctly

Apply suitable grease or oil to bearings and axle areas where allowed by design. Avoid over-lubricating in dusty or food-grade environments where attraction of contaminants or hygiene rules matter. Follow manufacturer guidance for sealed bearings.

Replace damaged parts before failure

If treads are chunking, hubs are cracked, or bearings feel rough, plan replacement during scheduled downtime instead of waiting for complete failure. Proactive replacement reduces sudden stoppages and emergency repair costs.

Looking to standardize your inspection process and cut recurring maintenance costs? Contact Humphries Casters today to find your ideal caster wheel for your business.

Maintenance minimizes existing risk, but procurement requires new insights. Here is a practical framework for selecting the right parts for complex, demanding operations.

How To Choose The Right Caster Wheels For Complex Operations

For complex operations, wheel parts must match real loads, floors, and duty cycles, not just catalog diagrams. A structured selection process helps you avoid trial and error.

Here’s how to choose:

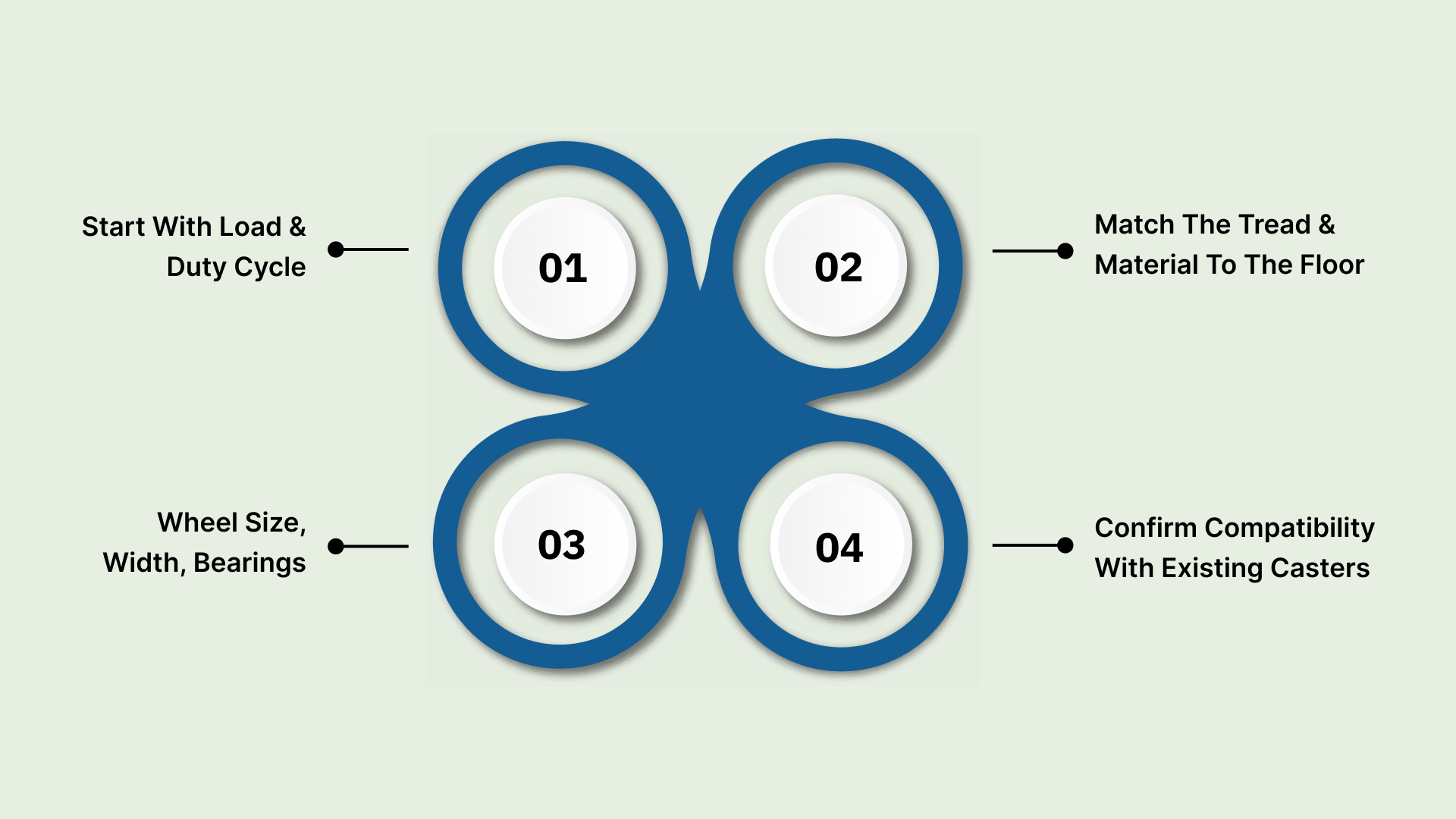

Start with load and duty cycle

Calculate your total equipment plus load weight and divide by the number of casters to find the minimum load per wheel. Then factor in duty cycle: distance traveled per shift, frequency of starts and stops, and typical peak loads.

Match the tread and material to the floor and environment

Select tread materials based on floor hardness, wet or dry conditions, and required noise level. For example, softer treads help protect delicate floors and reduce noise, while harder treads support higher loads on rough surfaces.

Specify wheel diameter, width, and bearing type

Choose diameter and width based on load, obstacles, and push-force targets. Larger diameters roll more easily over gaps and debris. Then match bearing type to speed, load, and contamination risks, such as sealed precision bearings for clean, high-use environments.

Confirm compatibility with existing casters

Before ordering, confirm wheel hub length, bore size, and axle diameter match your current caster forks. This ensures your replacement wheels fit your existing rigs without frame changes.

Humphries Casters: Solutions for Complex Mobility Challenges

Operations and maintenance teams often inherit mixed fleets of carts, racks, and specialized equipment with little documentation. When a wheel fails, the easiest option is to “match something close” from a catalog.

That shortcut usually increases push force, speeds up wear, or damages floors. Humphries Casters supports you by treating caster wheel parts as engineering inputs, not just commodity components.

Humphries Casters helps your operation by:

Consultative Approach: We focus on solving operational problems, not just pushing generic products.

Custom Engineering: We manufacture non-standard treads, cores, and axles to fit unique OEM and industrial needs.

Unmatched Sourcing: Access to over 400 global factories guarantees the right component for any specialized application.

Ergonomics Focus: Our solutions are designed to reduce push/pull force, minimizing staff fatigue and workplace injuries.

Reliability: We provide parts built for longevity, reducing maintenance cycles and operational downtime.

We offer comprehensive component coverage, enabling your team to consolidate vendors for all mobility and material handling requirements.

Conclusion

Understanding the intricate caster wheel parts, from the tread that touches the floor to the bearings that manage friction, is non-negotiable for operational leaders. Precise component specification prevents unnecessary downtime, enhances ergonomic safety.

It also protects your expensive facility flooring. Ignoring these six internal parts leads directly to costlier, reactive replacements. Humphries Casters is dedicated to partnering with Plant Managers and Engineers like you to eliminate parts guesswork.

We provide the expertise and specialized sourcing to ensure every axle, bearing, and tread performs to your exact standards.

Contact us today to get caster wheel parts that actually fit your equipment, your floors, and your safety goals.

FAQs

Q. When should I replace the entire caster versus just the wheel?

If the swivel raceway is seized, cracked, or wobbling, the entire caster assembly must be replaced. If the mounting plate or legs are bent, replace the entire unit. Replace only the wheel if the core, rig, and swivel function smoothly.

Q. How do I measure the wheel bore to ensure the bearing fits?

The bore is the inside diameter of the hole where the axle passes through the hub. Measure this diameter precisely, usually in fractions of an inch, to ensure the replacement bearing or bushing seats correctly.

Q. Can I upgrade my wheel bearings for better rollability?

Yes, upgrading from plain bushings to precision sealed ball bearings is a highly effective upgrade. This drastically reduces the necessary push-pull force, resulting in better ergonomics and reduced staff injury risk.

Q. What is a "kingpinless" caster, and why does it matter for parts?

A kingpinless caster eliminates the central bolt (kingpin) that holds the swivel together. This design is stronger, handles severe side-loading better, and requires fewer replacement parts for the swivel mechanism itself.

Q. Does the axle material affect the load capacity of the wheel?

Yes. While the wheel and bearings carry the load, the axle must be made of high-strength steel to resist bending under heavy compression. A bent axle causes immediate wheel failure and increased friction.

Q. Should I use different wheel materials for the front versus the back of a cart?

No. All wheels on the same equipment should have identical specifications, including material and diameter. Mixing materials or sizes compromises stability and causes uneven wear across the system.