When carts drag, vibrate, or damage your floors, the issue often isn’t the load; it’s the caster wheel type. A wheel that isn’t designed for your environment forces workers to push harder, increases floor wear, and leads to premature failure.

Industrial and commercial spaces demand different mobility performance, from quiet rolling in clean environments to shock absorption on rough floors. Choosing incorrectly results in downtime, safety concerns, and higher long-term maintenance costs.

This guide breaks down the key caster wheel types and how to match each one to your load, floor conditions, and operating environment, so your equipment moves smoothly and reliably every day.

Need to know

The best caster wheel is the one engineered specifically for your equipment’s load, floor type, and movement requirements.

Material choice directly influences floor protection, noise control, ergonomics, and wheel lifespan.

Correct mounting dimensions are essential to ensure proper fit and stable load distribution.

Real-world travel routes and obstacles must be considered to avoid performance failures.

Partnering with experts helps prevent costly mismatches and ensures long-term mobility reliability.

What “Caster Wheel” Really Means?

A caster wheel is more than just a round component that helps equipment move. It’s a mobility system designed to support load, protect floors, reduce worker effort, and maintain stability during movement. Each caster wheel type is engineered with specific performance characteristics that make it suitable for certain environments and operational demands.

Key features that define caster wheels:

Wheel Material: Determines durability, noise level, and floor compatibility.

Wheel Diameter & Width: Impacts load capacity, stability, and ease of rolling.

Bearing Type: Affects how smoothly and quietly the wheel rotates under load.

Caster Configuration: Swivel, rigid, or brake options change maneuverability and control.

Mounting System: Plate or stem design ensures proper fit and weight distribution.

Environmental Resistance: Performance in chemicals, moisture, heat, or freezing conditions.

Load Rating: Ensures the wheel can support both static and dynamic weight safely.

Understanding these features makes it easier to identify which caster wheel type will deliver the right performance for your equipment and facility needs.

Major Caster Wheel Types & Their Core Applications

Caster wheels are designed around how equipment moves, whether it needs precise directional control or flexibility in tight spaces. Choosing the right configuration ensures smooth operation, better safety, and reduced strain on workers.

1. Rigid Casters

Rigid casters roll in a straight line and do not swivel. They provide excellent stability when equipment needs to follow a predictable path.

Key Features:

Fixed orientation for controlled travel

High load stability

Durable and low-maintenance

Best For: Assembly lines, conveyors, and long travel paths where directional control is essential.

2. Swivel Casters

Swivel casters rotate 360°, allowing equipment to turn, pivot, and maneuver easily in confined spaces.

Key Features:

Full directional movement

Ideal for tight aisles and turns

Improves handling and agility

Best For: Warehouse picking carts, hospital equipment, and areas requiring frequent directional changes.

3. Swivel Casters with Brake / Total-Lock

These swivel casters include a braking system. Total-lock models secure both the wheel and swivel head to stop motion completely.

Key Features:

Enhanced operator safety

Secure stationary positioning

Prevents unwanted rolling on slopes or loading areas

Best For: Medical carts, workstations, and any application where stability during use is critical.

4. Pneumatic (Air-Filled) Casters

Pneumatic wheels provide cushioning that absorbs shock and vibration on uneven or outdoor terrain.

Key Features:

Smooth travel over rough surfaces

Better grip and ground contact

Protects transported goods from vibration damage

Best For: Construction sites, outdoor carts, and transport over gravel, expansion joints, or ramps.

5. Heavy-Duty / Industrial Metal-Core Casters

Designed for maximum strength, these caster wheels support high loads and continuous industrial use without deformation.

Key Features:

High load capacity

Strong impact and wear resistance

Minimal rolling deflection under weight

Best For: Manufacturing plants, machine bases, pallet trucks, and heavy load material movement.

6. Twin-Wheel / Dual-Wheel Casters

Twin-wheel casters use two wheels on one swivel assembly, distributing weight more evenly and improving maneuverability under heavy or uneven loads.

Key Features:

Better load distribution with reduced tread wear

Improved swivel action under high weight

Increased stability on uneven surfaces

Best For: Heavy equipment that must still maneuver easily, such as laboratory casework, data center racks, and high-capacity warehouse carts.

Struggling with floor damage or high push-force from your current wheels? Let Humphries Casters help you select casters engineered for safety, efficiency, and smooth mobility.

With caster types understood, the next step is choosing the wheel material that performs best in your operating environment.

Caster Wheel Materials: Advantages & Things to Consider

Wheel material has a direct impact on rolling effort, lifespan, and floor protection. Selecting the right material ensures smooth, efficient equipment movement, while choosing incorrectly can damage floors, create noise, and increase workload on operators.

Wheel Material | Advantages | Things to Consider | Best For |

Polyurethane (PU) | Strong load support; protects floors; low rolling resistance | Can harden in freezing temperatures | Warehouses, mixed floors, general industrial use |

Rubber | Quiet and smooth rolling; excellent grip on polished surfaces | Lower load capacity; wears faster under heavy use | Hospitals, retail, office environments |

Nylon / Plastic | Lightweight and cost-effective; easy rolling on smooth floors | Noisy; not suitable for uneven or rough surfaces | Light-duty carts in controlled indoor environments |

Cast Iron / Steel | Extreme durability; handles high temperatures and heavy loads | Can damage floors; louder operation | Manufacturing plants, heavy machinery |

Phenolic / Resin | Moisture and chemical resistant; strong under static load | Hard tread may mark soft flooring | Food processing, labs, cold storage facilities |

Pneumatic (Air-Filled) | Shock absorption for uneven or outdoor terrain | Requires inflation; lower load rating | Outdoor transport, sensitive equipment, rough floors |

Note: Material selection should always be validated against actual operating conditions, including weight distribution, travel distance, floor transitions, and exposure to moisture or chemicals. A wheel that performs well in one area of a facility may fail quickly in another.

How Floor Type Influences Wheel Material Choice

Floor conditions directly affect how well a caster wheel performs. Different surfaces require different levels of traction, protection, and durability. Choosing the right wheel material for your floor prevents excessive rolling resistance, floor damage, and premature caster wear.

Best Materials by Floor Condition:

Smooth Concrete & Polished Surfaces: Polyurethane wheels provide excellent traction and load support without marking floors, making them ideal for warehouses and commercial facilities.

Soft Floors (Vinyl, Tile, Epoxy-Coated Areas): Rubber wheels absorb vibration and minimize noise while protecting softer finishes from scuffs and scratches.

Rough Concrete, Asphalt & Uneven Industrial Surfaces: Cast iron or poly-on-iron wheels withstand abrasion and heavy impacts, maintaining stability in demanding environments.

Outdoor or Mixed-Terrain Routes: Pneumatic wheels absorb shock and provide grip over expansion joints, gravel, and ramps, ideal for carts frequently leaving the facility floor.

Cold Storage, Wet Floors, or Chemical Exposure: Phenolic or corrosion-resistant polyurethane maintains structure under moisture and temperature extremes, minimizing degradation over time.

Common Mistakes Buyers Make When Choosing Caster Wheels

Even when wheel size and weight rating seem correct, caster selection can still go wrong. Many problems become visible only after the wheels are in use, usually when stability, maneuverability, or floor condition starts to decline. Avoid these frequent mistakes to prevent operational setbacks.

Choosing by Price Instead of Performance: Lower-cost casters may fail faster under load or stress. What appears to be savings upfront often turns into higher maintenance and downtime costs.

Ignoring Environmental Conditions: Wheels that perform well indoors may crack in cold storage, warp in humidity, or deteriorate under chemical exposure, leading to unexpected failures.

Overlooking Floor Compatibility: Hard wheels on soft flooring cause gouges, while soft wheels on rough surfaces wear out quickly. Always match wheel hardness to floor type.

Mixing Different Wheel Types on the Same Equipment: Combining swivel and rigid casters incorrectly or mixing new and worn tread heights causes instability, drifting, and uneven load distribution.

Not Considering Operator Ergonomics: Even a properly sized caster can increase worker fatigue if rolling resistance is too high, slowing down workflows and elevating injury risks.

Taking the time to specify the right caster wheel type prevents replacement cycles and reduces operational strain.

Avoid downtime and performance issues caused by incorrect caster wheels. Get accurate specifications and long-lasting caster solutions from Humphries Casters.

Six Pro Strategies for Specifying the Right Caster Wheel

Selecting casters becomes easier when you evaluate how equipment performs under real-world conditions rather than relying only on catalog numbers. These practical guidelines help ensure the wheel you choose delivers lasting performance and safety.

Calculate Real Dynamic Load, Not Just Static Weight: Equipment rarely sits perfectly level. Use the three-caster rule to avoid overload when weight shifts during movement.

Validate Mounting Specifications Before Ordering: Confirm plate size, bolt pattern, stem diameter, and overall mounting height; even small differences affect fit and stability.

Test Wheel Function on Actual Routes: Floor transitions, ramps, and debris expose performance issues that aren’t visible on paper.

Standardize Specifications Across Facilities: Consistent caster selection simplifies maintenance and prevents mismatched replacements that cause uneven wear.

Prioritize Rolling Efficiency and Safety: Lower rolling resistance reduces operator strain, improves handling, and supports OSHA-aligned ergonomics goals.

Replace All Casters as a Set: Combining worn wheels with new ones disrupts load distribution, causing faster failure and unpredictable movement.

These best practices ensure your caster selection supports both equipment performance and frontline worker productivity.

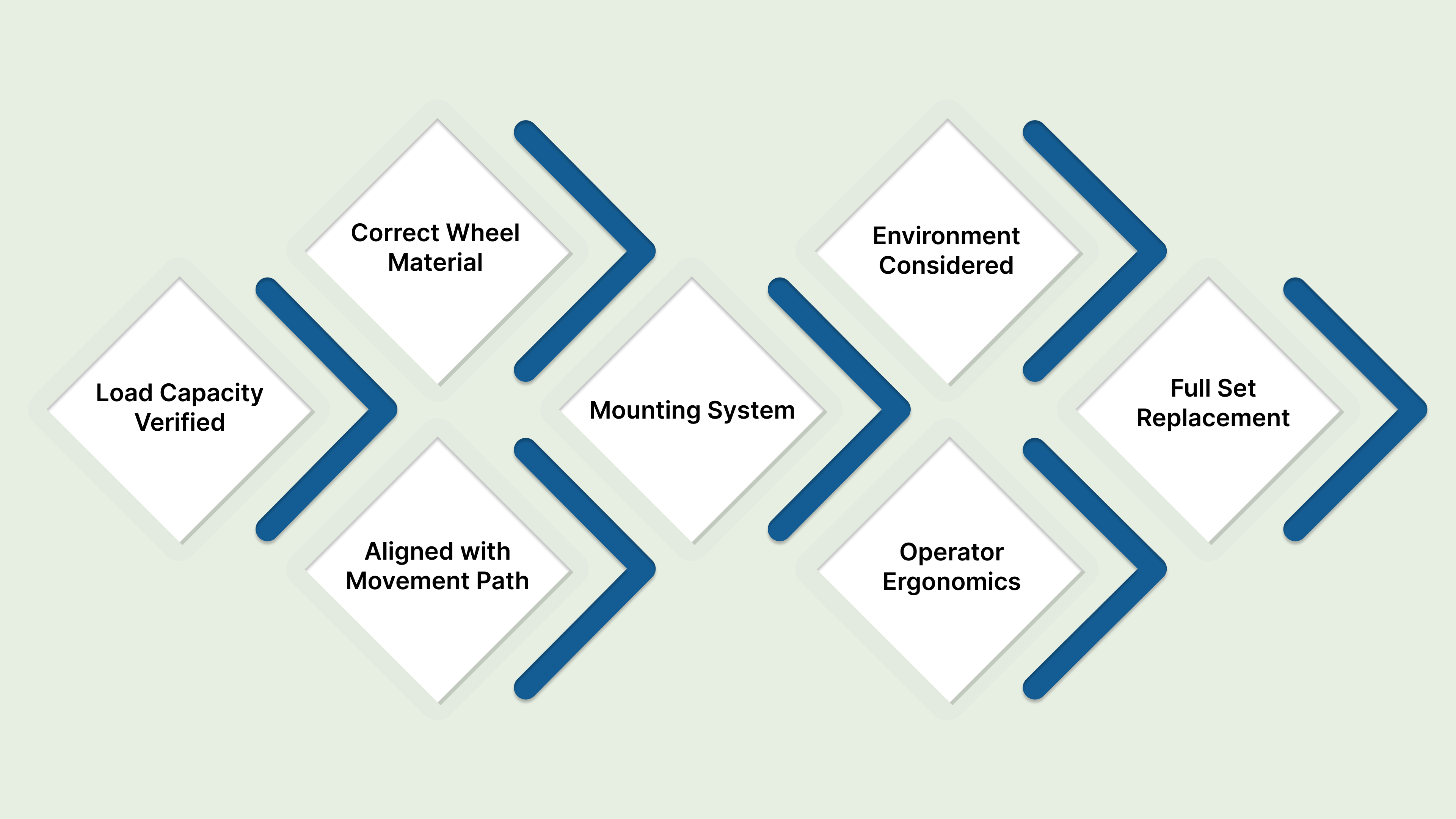

Quick Caster Wheel Selection Checklist

Before placing a purchase order, a fast specification check can prevent installation failures, workflow disruptions, and unnecessary replacement costs. Use this checklist to confirm whether the caster wheel type is suitable for your operating conditions:

Checklist:

Load Capacity Verified? Confirm the total weight (equipment + max load) and apply the three-caster rule for safe distribution.

Correct Wheel Material for Floor Type? Choose based on floor hardness, noise sensitivity, and risk of floor marking.

Swivel vs. Rigid Configuration Aligned with Movement Path? Consider aisle width, turning radius, and directional control requirements.

Mounting System Confirmed? Match plate size, bolt hole pattern, stem diameter/length, and overall mounting height.

Environment Considered? Check exposure to water, chemicals, heat, cold, or outdoor elements.

Operator Ergonomics Evaluated? Ensure rolling resistance and stability support safe handling and efficiency.

Full Set Replacement Planned? Replace all casters together to avoid uneven load and movement problems.

If any box in the checklist raises uncertainty, consulting a caster specialist like Humphries Casters ensures you can avoid costly missteps.

How Humphries Casters Helps You Specify the Right Caster Wheel

Every facility operates differently, and the caster wheel must match those conditions with precision. Humphries Casters supports industrial and commercial buyers with solutions engineered for safe, efficient, and long-lasting equipment mobility.

What You Can Expect From Humphries Casters:

Technical Specification Support: We assess your load, floor conditions, mobility needs, and environment to ensure the right wheel is selected the first time.

Reliable, Application-Matched Products: From general-purpose mobility to demanding industrial environments, we provide caster wheels designed to perform and endure.

Mounting Compatibility Assistance: Plate sizes, bolt patterns, stem fittings, every detail is checked to prevent installation issues and operational delays.

Ergonomics & Safety Focused: Lower push-pull effort improves handling efficiency and reduces strain on operators.

If you're replacing casters due to wear issues, floor damage, or handling concerns, it may be time to upgrade the specification, not just the wheel.

Final Words

Selecting the right caster wheel type prevents unnecessary labor, protects surfaces, and keeps your equipment operating smoothly. When mobility performance affects productivity and safety, expert guidance becomes an essential part of the solution.

Get in touch with Humphries Casters for accurate caster wheel recommendations and reliable components tailored to your application. At Humphries Casters, our team is ready to support your equipment with wheels that are built to perform and engineered to last.

FAQs

1. What is the most important factor when choosing caster wheels?

Load capacity and floor type are the top priorities. The wheel material must match the surface it rolls on, and the wheel must safely support both static and dynamic loads.

2. Can I mix different caster wheel types on the same equipment?

No. Mixing rigid and swivel casters incorrectly, or combining new and worn wheels, leads to imbalance, poor tracking, and uneven load distribution.

3. How do I prevent caster wheels from damaging floors?

Select softer, non-marking materials like polyurethane or rubber for sensitive surfaces, and ensure the wheel hardness is appropriate for your flooring.

4. When should casters be replaced?

Replace casters when rolling resistance increases, wheels develop flat spots or cracks, noise rises, or carts begin leaning. Early action prevents safety risks and downtime.

5. Do temperature and chemicals affect caster performance?

Yes. Cold storage, heat, moisture, and chemicals can cause material breakdown. Always choose wheels rated for the specific environment where they will be used.