Your facility’s efficiency often grinds to a halt because of a single component: the wheel. You might struggle to push a heavy cart across a concrete floor, or perhaps a medical cart is vibrating so much that it damages sensitive equipment.

These issues rarely stem from the cart itself, but from choosing the wrong wheel hardness for the environment. Selecting between soft and hard casters is not just a preference; it is an operational necessity.

The wrong choice leads to damaged floors, excessive noise, increased push forces that injure workers, and rapid wheel failure. You need to match the durometer (hardness) of the wheel to your specific floor conditions and load requirements.

In this guide, we break down the critical differences between soft casters vs hard casters. You will learn exactly which type suits your industrial application, ensuring you protect your floors, your equipment, and your team.

Key Takeaways (TL;DR)

The Golden Rule: Use soft wheels on hard floors (tile, concrete, epoxy) and hard wheels on soft surfaces (carpet, dirt, gravel) to maximize performance.

Load Capacity: Hard casters (nylon, steel) support significantly heavier loads than soft casters, which can compress and flatten under extreme weight.

Ergonomics: Hard casters roll easier (lower starting resistance), reducing the force needed to start moving a heavy cart. Soft casters require more effort to push.

Noise Control: Soft casters absorb vibration and are essential for quiet environments like hospitals; hard casters transmit noise and can be extremely loud on concrete.

Floor Protection: Soft casters (TPR, rubber) prevent scratches and cracking on expensive finished floors. Hard casters can gouge or mark delicate surfaces.

Debris Rejection: Soft casters tend to roll over small debris (metal chips, screws), whereas hard casters can grind debris into the floor or stop abruptly.

What Are Soft Casters?

Soft casters are manufactured from resilient materials like thermoplastic rubber (TPR), soft polyurethane, or pneumatic rubber. They are designed to yield slightly under load, providing a cushioning effect. They are best suited for indoor environments where floor protection and noise reduction are critical.

Advantages:

Floor Protection: They will not scratch, mar, or crack sensitive flooring like hardwood, tile, or epoxy.

Noise Reduction: The soft material absorbs vibration, making it virtually silent during operation.

Shock Absorption: They act as a cushion, protecting fragile loads (electronics, glass) from jarring impacts.

Debris Rejection: Soft treads can often roll over small obstacles like zip ties or metal shavings without locking up.

High Traction: They provide excellent grip on slick or wet surfaces, preventing carts from sliding.

Disadvantages:

Higher Rolling Resistance: They flatten slightly under weight, requiring more physical effort to start and keep moving.

Lower Load Capacity: They cannot support the extreme weights that steel or nylon can handle without deforming.

Durability Concerns: Soft materials tear, chunk, or wear down faster on rough, abrasive concrete.

Chemical Sensitivity: Certain rubbers degrade quickly when exposed to oils, grease, or harsh industrial solvents.

Flat Spotting: If left stationary under load for too long, they can develop permanent flat spots.

Ideal Applications:

Medical Carts: IV stands and crash carts in quiet hospital wings.

Office Furniture: Chairs and light-duty carts on hardwood or tile.

Retail Displays: Point-of-purchase displays on polished showroom floors.

While soft casters cushion the ride, industrial environments often demand the sheer strength and resilience of the opposite material.

What Are Hard Casters?

Hard casters are constructed from rigid materials such as cast iron, forged steel, phenolic resin, or nylon. They are built for durability and ease of movement. These wheels are the standard for heavy industrial manufacturing, where loads are high and floors are rough.

Advantages:

High Load Capacity: They can support thousands of pounds per caster without deformation.

Low Rolling Resistance: The rigid surface creates minimal friction, making it very easy for workers to push heavy loads.

Extreme Durability: They resist wear, tearing, and flat-spotting, even in abusive environments.

Chemical & Heat Resistance: Materials like steel and high-temp phenolic withstand extreme heat and corrosive chemicals.

Cost-Effective: For basic heavy-duty needs, hard materials like polyolefin are often cheaper than specialized soft treads.

Disadvantages:

Floor Damage: They can scratch, dent, or crush expensive floor finishes like vinyl or epoxy.

High Noise Levels: Hard wheels on concrete create significant noise, which can be a safety hazard or nuisance.

Vibration Transmission: Every crack and bump is felt by the cart and the operator; no shock absorption.

Poor Traction: They can slide easily on wet or slick floors, making control difficult on ramps.

Debris Sensitivity: A small rock or screw can stop a hard wheel dead in its tracks, causing the load to tip.

Ideal Applications:

Heavy Manufacturing: Transporting raw materials or heavy machinery parts.

Warehousing: Pallet jacks and platform trucks on smooth concrete.

High-Temp Ovens: Racks entering powder coating ovens or autoclaves.

Knowing the definitions is helpful, but making the right choice requires a side-by-side analysis of nine critical performance factors.

Stop compromising between load, noise, and floor protection. Humphries Casters has sourced solutions for 27 years. Get in touch for help finding your perfect caster.

Soft Casters vs Hard Casters: A Comparison

The differences between soft and hard casters extend far beyond feel. Each material choice affects how your equipment moves, how long it lasts, and whether your floors survive the experience.

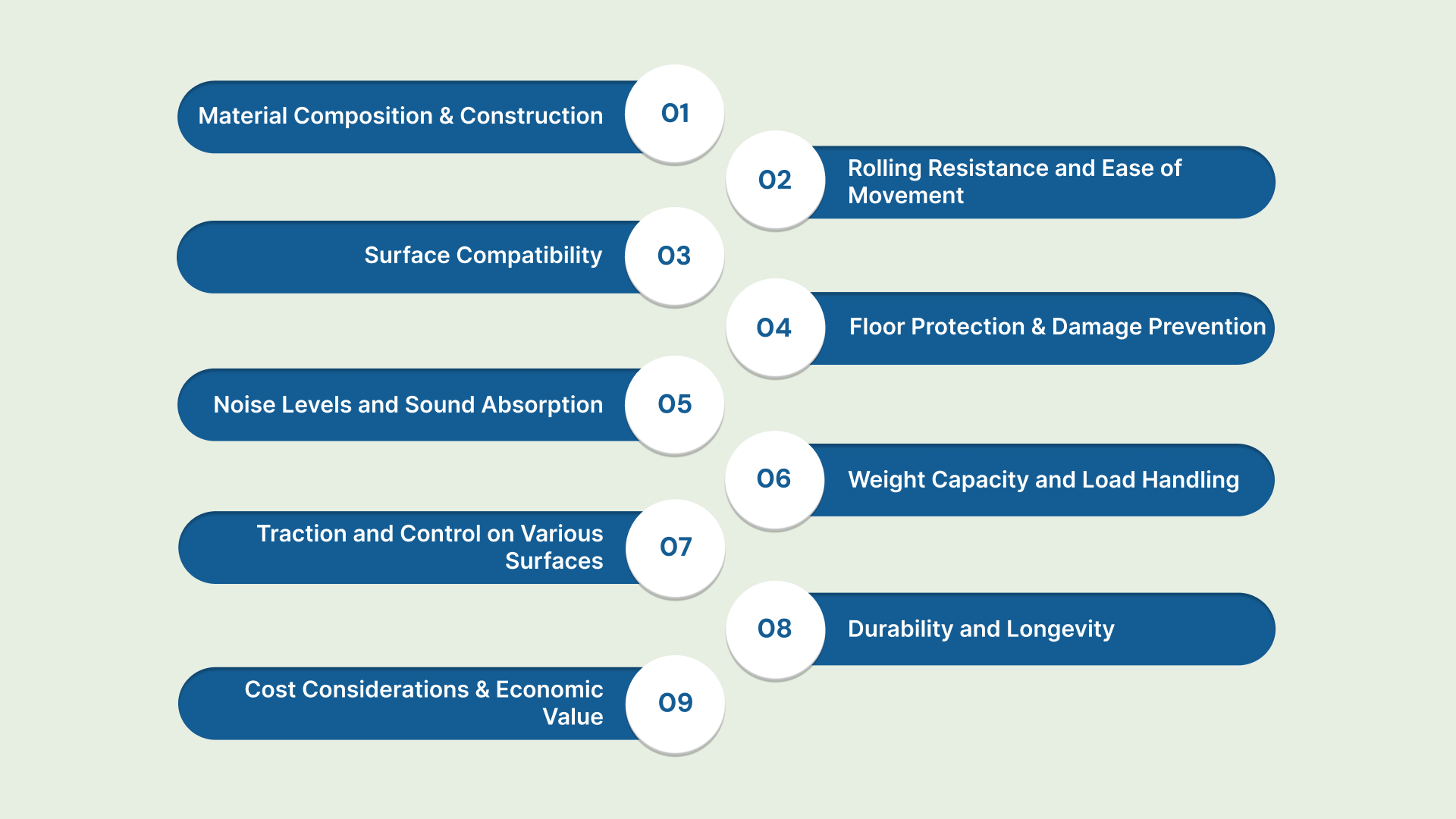

Here's how they stack up across nine critical performance factors:

Material Composition and Construction

Soft casters use flexible materials to absorb impact; hard casters use rigid materials for strength and durability.

Soft Casters:

Made from rubber, polyurethane, thermoplastic, or soft nylon compounds.

Feature cushioned, compliant treads that conform to floor irregularities.

It can be formulated in varying hardness levels (80A-95A Shore durometer).

Hard Casters:

Cast from iron, nylon, polypropylene, or hard polyurethane.

Rigid construction resists deformation under extreme loads.

Maintain consistent shape and performance across temperature ranges.

Rolling Resistance and Ease of Movement

Hard casters roll with less effort; soft casters require more force but offer better controlled stopping.

Soft Casters:

Increased rolling resistance requires more initial push force to start moving.

Provide natural braking, preventing runaway equipment on slight inclines.

Better control in crowded spaces where precision is critical.

Hard Casters:

Low rolling resistance means minimal effort to move heavy loads across smooth floors.

Continue rolling freely once in motion, reducing operator fatigue during long shifts.

Require active braking systems to prevent drift on uneven or inclined surfaces.

Surface Compatibility

Soft casters work best on hard floors; hard casters roll smoothly on any surface, but damage soft floors.

Soft Casters:

Excel on tile, linoleum, epoxy, polished concrete, and hardwood.

Struggle on carpet, sinking or sticking without special mats.

Perform well on outdoor asphalt and uneven terrain.

Hard Casters:

Roll easily on carpet, offering low resistance in office environments.

Causes noise and potential damage on hard floors like tile and concrete.

Perform well on industrial metal grating and outdoor concrete.

Floor Protection and Damage Prevention

Soft casters protect delicate floors; hard casters can cause permanent scratches and gouges.

Soft Casters:

Non-marking wheels prevent discoloration and cosmetic damage on light-colored floors.

Absorb impact, preventing indentation caused by heavy stationary loads.

Distribute weight effectively, protecting epoxy coatings and sealers.

Hard Casters:

Can scratch, chip, and gouge delicate flooring materials.

Create grinding marks where debris becomes trapped between the wheel and floor.

May damage expensive finishes like polished concrete or hardwood.

Noise Levels and Sound Absorption

Soft casters operate silently; hard casters generate noise proportional to floor hardness.

Soft Casters:

Absorb vibrations naturally, reducing ambient noise by 10-20 decibels.

Create pleasant, quiet movement ideal for patient recovery and focused work.

Particularly effective on tile, concrete, and metal surfaces.

Hard Casters:

Generate significant noise on hard floors, ranging from clicking to loud clattering.

Noise increases with floor damage, uneven surfaces, or debris.

Require sound-dampening mats or barriers in noise-sensitive environments.

Weight Capacity and Load Handling

Hard casters carry 2-3x more weight than soft casters before performance degrades.

Soft Casters:

Maximum load capacity typically 300-500 lbs per wheel, depending on material and size.

Can compress under excessive weight, causing flat-spotting and loss of rollability.

Suitable for light-to-medium duty applications in healthcare and retail.

Hard Casters:

Handle 1,000+ lbs per wheel, making them ideal for heavy machinery and fully loaded pallet jacks.

Maintain shape and performance even when left stationary under maximum load.

Engineered for continuous heavy-duty use without capacity limitations.

Traction and Control on Various Surfaces

Soft casters provide superior grip; hard casters can slide on slippery surfaces.

Soft Casters:

A high friction coefficient offers secure grip on wet, oily, or smooth surfaces.

Prevent equipment from drifting on loading docks, ramps, or inclines.

Ideal for environments where unexpected sliding creates safety risks.

Hard Casters:

A lower friction coefficient allows easy sliding and precise maneuverability in dry conditions.

Can slip on wet floors, oily surfaces, or smooth concrete without traction aids.

Require special brake systems or friction mats for safety on hazardous surfaces.

Durability and Longevity

Hard casters last significantly longer under heavy, continuous use.

Soft Casters:

Wear down faster, especially on rough concrete or under heavy loads.

May develop flat spots, tears, or chunking after 12-18 months of heavy use.

Require replacement more frequently, increasing long-term maintenance costs.

Hard Casters:

Resist abrasion, maintain structural integrity, and last 3-5 years or more.

Minimal wear even under continuous heavy use on industrial floors.

Lower replacement frequency means reduced maintenance cycles and costs.

Cost Considerations and Economic Value

Hard casters cost less upfront; soft casters provide better ROI by preventing floor damage.

Soft Casters:

Higher initial purchase price per unit.

Prevent expensive floor repairs, reducing the total cost of ownership.

Better long-term value for healthcare, retail, and sensitive floor environments.

Hard Casters:

Lower upfront cost per unit makes them budget-friendly.

May require floor restoration or replacement over time.

Best value for heavy-duty industrial use where floor protection isn't a priority.

Characteristic | Soft Casters | Hard Casters |

Material | Rubber, polyurethane, nylon, thermoplastic | Cast iron, nylon, polypropylene, hard polyurethane |

Load Capacity | 300-500 lbs per wheel | 1,000+ lbs per wheel |

Rolling Resistance | High (requires more initial force) | Low (minimal effort to move) |

Noise Level | Very quiet (10-20 dB reduction) | Loud, especially on hard floors |

Floor Protection | Excellent (non-marking) | Poor (can damage delicate floors) |

Shock Absorption | Excellent (cushion impacts) | Minimal (transmits vibration) |

Traction | Excellent grip on smooth surfaces | Low friction (can slip) |

Durability | 12-18 months of heavy use | 3-5 years of heavy use |

Best For | Healthcare, retail, and offices | Warehouses, manufacturing, rugged environments |

Upfront Cost | Higher per unit | Lower per unit |

Long-term ROI | Better (prevents floor damage) | Lower (may require floor restoration) |

Not sure which column matches your operation? We work with caster and wheel factories around the globe, so we can offer you the right caster at the right price. Contact us for help navigating soft vs hard casters.

Understanding these technical trade-offs is essential, but applying them to your specific facility requires a structured decision-making process.

How to Choose the Right Caster for Your Industrial Needs?

Selecting the correct caster is a formula, not a guess. Follow these steps to ensure you buy the right component:

Audit Your Floor Conditions: Walk your facility. Is the floor polished concrete, epoxy, or rough asphalt? If the floor is harder than the wheel, the wheel wears. If the wheel is harder than the floor, the floor wears. Choose the sacrificial part: usually, you want the wheel to wear, not the floor.

Calculate Required Load Capacity: Take the total weight of your cart and the maximum load. Divide by three (not four). This provides a safety factor for uneven floors where one wheel might lose contact. If this number is high (>1000 lbs), you are likely pushed toward hard casters.

Determine Allowable Noise Levels: Are you in a customer-facing area, a hospital, or a loud foundry? If silence is required, you must sacrifice some load capacity for soft rubber or TPR wheels. In a loud factory, hard nylon is acceptable.

Assess Environmental Hazards: Look for oil, grease, acid, or extreme heat. Hard casters (like steel or phenolic) survive high heat and chemicals. Soft rubber will melt or degrade in these conditions.

For more insights on choosing a caster, refer to this quick guide.

Even with a solid framework, balancing unique floor types with heavy loads often requires specialized sourcing capabilities.

Why Choose Humphries Casters

Generic industrial catalogs force you to choose between "standard option A" or "standard option B," often leaving you with a caster that protects the floor but fails under load, or carries the load but deafens your staff. You shouldn't have to compromise on safety or efficiency.

Humphries Casters provides the exact wheel formulation your operation requires. Here's why you should choose us:

Global Sourcing: We access 400+ factories to find niche materials, from non-marking high-load poly to heat-resistant phenolics.

Custom Solutions: If a standard hard or soft wheel doesn't fit, we engineer a custom durometer to balance grip and rollability.

Safety Focus: We help you calculate ergonomic push forces to keep your team injury-free.

Reliability: We deliver components that last, reducing your maintenance downtime.

We ensure you get the right mobility solution, protecting your floors, your people, and your bottom line.

Conclusion

The choice between soft casters vs hard casters dictates the safety and speed of your workflow. Soft casters are the clear winner for floor protection, noise reduction, and light-to-medium loads in sensitive environments.

Hard casters are the non-negotiable choice for extreme loads, durability, and ease of rolling in rugged industrial settings. The choice between soft casters vs hard casters isn't about which is objectively better. It's about matching material properties to your specific environment, load, noise tolerance, and floor conditions.

Making the wrong choice results in operational friction, damaged floors, or equipment that underperforms your expectations.

Humphries Casters eliminates the guesswork. We analyze your specific floor type, load requirements, and environmental constraints to recommend the perfect wheel. Contact us today to optimize your material handling equipment and extend the life of your facility floors.

FAQs

Q. Can I use soft casters on carpet?

Soft casters can work on carpet but require additional floor mats or protection. The soft tread tends to sink into the carpet pile, making rolling difficult. Hard casters roll much more easily on carpet.

Q. Are soft casters always better for floor protection?

Yes, soft casters provide better floor protection. However, if your load exceeds 500 lbs per wheel, soft casters may compress and flat-spot, potentially causing damage. Hard casters with protective mats may be necessary.

Q. Why do hard casters cost less than soft casters?

Hard casters use simpler materials and manufacturing processes. Soft casters require specialized formulations and more precise engineering, driving up production costs.

Q. Can I mix soft and hard casters on the same equipment?

No. Mixing caster types creates uneven rolling, unstable equipment movement, and accelerated wear. Use identical caster types across all wheels on one equipment piece.

Q. What's the best caster for a healthcare facility with occasional heavy loads?

Soft casters remain the priority for noise and floor protection in healthcare. However, if occasional loads exceed 500 lbs per wheel, consider a softer polyurethane caster (82-85A Shore hardness) that balances load capacity with noise reduction.