Moving heavy equipment or furniture in tight spaces can be challenging. Whether it's in a warehouse, hospital, or office, efficient movement is crucial to maintaining productivity. Finding the right solution can save time and reduce manual effort.

What are casters? They are specialized wheels that provide multidirectional movement, making it easier to move bulky items across various surfaces. But understanding the difference between casters and simple wheels is key to making the right choice.

Choosing the wrong caster can lead to instability and inefficiency. This guide explains everything you need to know about casters, from types and applications to how they differ from wheels, ensuring you select the best option for your needs.

Quick look

Casters provide multidirectional movement, unlike wheels, making them ideal for maneuvering in tight spaces.

Key types of casters include swivel, rigid, plate, stem, locking, and kingpinless, each suited for different applications.

The right caster choice depends on load capacity, floor type, maneuverability, and environmental conditions.

Materials like rubber, polyurethane, and steel impact durability, noise reduction, and load-bearing capacity.

Consider factors like stability, size, and material to avoid issues like wear or instability.

What is a Caster?

A caster is a type of wheel mounted on a swivel bracket, allowing it to rotate in multiple directions. This design provides improved mobility, making it easier to move heavy or bulky items across various surfaces.

Casters are used in a wide range of applications, from office furniture to industrial equipment, offering flexibility that traditional wheels cannot.

Now that we understand what a caster is, let's explore how casters differ from simple wheels in terms of movement and functionality.

Casters vs. Wheels: Key Differences

Casters and wheels may seem similar, but they serve distinct purposes. While both enable movement, casters provide more flexibility and maneuverability, especially in tight spaces. Understanding these differences is crucial for choosing the right option for specific applications.

Here's a quick comparison of the key differences between casters and wheels:

Aspect | Casters | Wheels |

Movement | Multidirectional (360-degree rotation) | Typically, move in a single direction |

Design | Swiveling bracket and mounting system | Simple, non-rotating wheel |

Functionality | Ideal for navigating tight or complex spaces | Best for straight-line movement |

Applications | Office furniture, medical carts, industrial equipment | Vehicles, carts, trailers |

Mounting | Requires a mounting system (plate or stem) | Directly attached to the equipment or vehicle |

With these key differences in mind, let’s now look into the most common types of casters and how they’re used in various industries.

Common Types of Casters

Casters are available in different types, each suited to particular applications and environments. Choosing the right type ensures efficient performance and safety for the equipment being used.

Below are the most common types of casters:

Swivel Casters: These casters rotate 360 degrees, providing maximum maneuverability in tight spaces. They are ideal for applications requiring flexible movement, such as office furniture and hospital carts.

Rigid (Fixed) Casters: Fixed casters allow for straight-line movement, making them perfect for situations where controlled movement along a fixed path is needed. They're commonly used in assembly lines and heavy-duty industrial equipment.

Plate Casters: Plate casters have a robust mounting plate, making them suitable for heavy-duty applications. These are typically used in machinery and industrial equipment that require a secure and durable caster.

Stem Casters: Stem casters are equipped with a stem that fits directly into the equipment. They're commonly found in office furniture and light-duty applications due to their ease of installation and versatility.

Locking Casters: Locking casters have a mechanism that secures the wheel in place, preventing movement once positioned. These are used in medical equipment, mobile carts, and furniture that need to stay stationary.

Kingpinless Casters: These casters are built without a central pin, providing increased durability and weight capacity. They are perfect for industrial applications where heavy loads and tough environments are common.

Now that you know the various types of casters, let's take a look at their key uses and applications across different industries.

5 Key Uses and Applications of Casters

Casters are essential in many industries, offering mobility and flexibility for equipment and machinery. Whether it's making office furniture easier to move or helping heavy machinery glide across factory floors, casters are integral to smooth operations.

Here’s a look at some key applications:

Office Furniture

Casters are used in office chairs (allowing employees to move freely and adjust seating position) and mobile desks (enabling easy reconfiguration of office layouts). For example, ergonomic office chairs often have swivel casters that allow users to move easily between workstations.

Medical Equipment

Hospital beds, medical carts, and IV poles rely on casters for smooth, quiet movement. These casters often come with locking mechanisms to secure equipment in place, especially in patient rooms or operating areas.

For example, hospital carts with locking casters ensure safety while transporting medical supplies.

Industrial Settings

In factories and warehouses, casters help move heavy machinery, storage racks, and trolleys loaded with materials. Casters in this setting must be durable and capable of supporting significant weight.

For instance, heavy-duty plate casters are commonly used in manufacturing plants to transport machinery parts or large components.

Retail and Hospitality

Casters are used in display units, shopping carts, and mobile food carts. In restaurants, casters are often seen in food prep carts, allowing staff to easily move equipment.

In retail, display racks with casters make it easier for store owners to rearrange product displays or change layouts frequently.

Specialized Environments

Casters are customized for environments such as clean rooms, laboratories, and food processing.

For example, in cleanrooms, casters are often made from non-marking rubber to prevent contamination, and they may need to withstand frequent cleaning and sterilization.

Next, let's explore the materials used in casters and wheels, and how the right material can impact performance and longevity.

Materials Used in Casters and Wheels

The material used in casters and wheels directly affects their durability, load capacity, and performance in various environments. Selecting the right material ensures that casters can handle specific conditions, such as weight, floor type, and exposure to chemicals or moisture.

Here are the most common materials used:

Rubber: Rubber casters provide a smooth, quiet ride and are ideal for sensitive surfaces. Commonly used in office furniture, medical carts, and retail displays.

Polyurethane: Durable and wear-resistant, polyurethane is perfect for heavy-duty industrial casters that need to withstand constant movement and rough surfaces, such as in warehouses and material handling.

Steel: Steel casters are designed for extreme loads and heavy-duty applications. They're frequently used in industrial settings and for heavy machinery transport.

Polyolefin: A lightweight and resistant material, polyolefin is commonly used in cleanrooms, laboratories, and food processing, where durability and chemical resistance are key.

Nylon: Known for strength and lightweight properties, nylon casters are used in food service carts and light-duty industrial applications, offering abrasion resistance and smooth movement.

Phenolic: Phenolic casters are heat-resistant and durable, ideal for high-temperature environments and heavy-duty equipment in manufacturing.

Choosing the right material ensures the caster performs well for its intended application. Next, let's look at how to choose the right caster based on your specific needs.

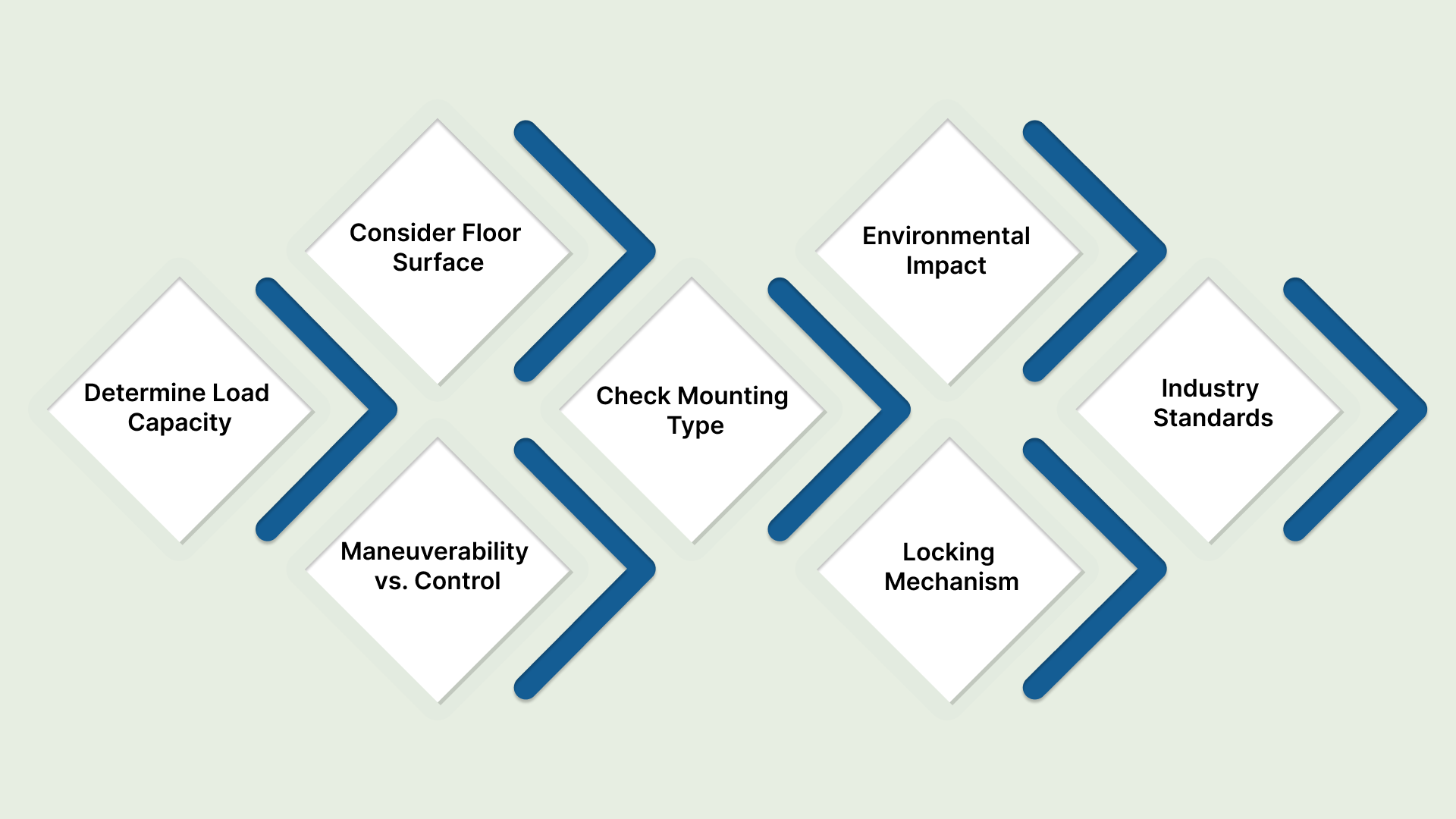

How to Choose the Right Caster: 7 Key Factors to Consider

Selecting the right caster is crucial for ensuring smooth movement, stability, and safety in any application. By considering factors like load capacity, maneuverability, and environmental conditions, you can avoid issues like premature wear or instability.

Here's a checklist to help you choose the best caster for your needs:

Determine Load Capacity: Ensure the caster can support the total weight of the equipment or furniture, including any dynamic forces (e.g., moving over bumps or uneven surfaces). Choose a caster with a load capacity slightly higher than the total weight.

Consider Floor Surface: Different floor types (concrete, carpet, tile, etc.) require different caster materials. For example, use polyurethane casters for smooth floors and rubber casters for soft or uneven surfaces.

Evaluate Maneuverability vs. Directional Control: If easy maneuvering is important, opt for swivel casters. For controlled, straight-line movement, rigid casters are ideal.

Check Mounting Type: Choose between plate casters (for heavy-duty equipment) and stem casters (for lighter, movable items like office chairs). Ensure the mounting type fits the equipment design.

Assess Environmental Factors: Consider environmental conditions such as exposure to moisture, chemicals, or extreme temperatures. For such environments, select casters made of materials like polyolefin or phenolic that offer chemical and heat resistance.

Locking Mechanism: If stability is important, choose locking casters to prevent unintended movement. Locking casters are especially important for medical equipment and carts.

Industry Standards: Casters must meet industry-specific standards for safety and performance. For instance, medical equipment casters follow FDA guidelines, while industrial casters may comply with ISO 9001 or ANSI/ASME B30.9 for material handling. Choosing compliant casters ensures reliability and safety.

Looking for the right casters? Humphries Casters provides a range of high-quality casters designed for various applications, ensuring you find the perfect match for your needs. Explore our range of casters here.

Let’s now explore some key considerations when using casters in various applications.

Limitations and Considerations When Using Casters

While casters are highly effective, they come with certain limitations that need to be considered to ensure optimal performance. Factors such as stability, load capacity, and material selection can impact their efficiency.

Here are key limitations to keep in mind:

Stability Issues with Swivel Casters: Swivel casters can sometimes cause instability, especially under heavy loads or when moving at high speeds. Ensuring proper load distribution helps mitigate this.

Incorrect Size or Material: Choosing the wrong caster size or material for your equipment or floor type can lead to premature wear or damage. Always match the caster to the intended environment and weight capacity.

Height and Stability Concerns: Casters can affect the height and stability of the equipment. Ensure the equipment is balanced, especially in environments with uneven floors.

Limited Maneuverability on Certain Surfaces: Some casters, like those made from hard materials, may perform poorly on soft or uneven surfaces.

Having considered the potential limitations of casters, it's important to choose a reliable supplier that can provide solutions personalized to your specific needs.

Let's now look at why Humphries Casters is the ideal partner for your mobility solutions.

Why Choose Humphries Casters for Your Mobility Solutions?

Humphries Casters is a trusted provider of high-quality, custom mobility solutions designed to meet the unique needs of industries like healthcare, manufacturing, and retail. They offer durable casters built for efficiency, safety, and smooth operation in demanding environments.

Here’s what they offer:

Custom Caster Solutions: Humphries Casters designs customized casters for specific applications, ensuring optimal performance in industries like healthcare and manufacturing.

Extensive Selection of Durable Casters: They offer a wide range of casters, from heavy-duty models for industrial settings to stainless steel casters for cleanrooms and food processing.

Expert Support and Guidance: Humphries Casters provides personalized assistance to help businesses select the right casters, ensuring compatibility with equipment and environments.

Humphries Casters provides reliable, custom mobility solutions that improve operational efficiency and safety across industries.

Wrapping Up

Casters are vital for ensuring smooth movement and flexibility in various industries, from office furniture to industrial equipment. Knowing what casters are, their types, and how they differ from wheels helps in making the right choice based on load capacity, material, and environment.

Humphries Casters offers a wide range of durable, custom solutions personalized to your specific needs. Whether for healthcare, industrial settings, or retail, they provide expert assistance to ensure you choose the perfect caster.

Send photos for a spec match and get expert guidance on selecting the perfect caster for your equipment.

FAQs

Can casters damage certain types of flooring?

Yes, hard‑tread casters (e.g., steel, hard plastic) can scratch or mark sensitive floors like hardwood, vinyl or tile. For smooth or delicate surfaces, softer treads (like rubber or polyurethane) help protect the floor and reduce noise.

How do I know if my caster's wheel diameter is appropriate for my use case?

Wheel diameter affects ease of rolling and ability to handle rough floors or obstructions. Larger wheels roll more smoothly over uneven surfaces and reduce push effort; smaller wheels are suitable only for light loads and smooth floors.

Do all casters handle heavy loads equally well?

No. Load capacity depends on caster design, wheel material, and bearing type. Heavy-duty or industrial casters (with reinforced structure and strong materials) are designed for large loads, while lighter casters are only suitable for lighter furniture or equipment.

How often should caster wheels be inspected or maintained for safety?

Regular inspections, checking for wheel wear, debris, loose bolts, and smooth swivel action should be done periodically (e.g., every few weeks in heavy-use settings) to prevent accidents and ensure caster longevity.

Are casters "universal," meaning can I swap any caster for any piece of equipment?

Not always. Casters vary in mounting type (plate vs. stem), wheel size, load rating, and material. Swapping without matching specifications can lead to poor performance or instability. Always check that caster specs match your furniture or equipment requirements before replacement.