Your warehouse team struggles to move a heavy pallet cart smoothly. Halfway through the shift, the wheels stick. By day's end, workers are exhausted and at risk of injury. You realize the casters are wrong, but don't know how to measure them correctly.

Incorrect caster measurements lead to equipment failure, worker strain, and unexpected downtime. Getting measurements right ensures you choose casters that match your actual needs: safe wheels, proper load capacity, and smooth operation. This saves money, reduces injuries, and keeps operations running.

In this guide, you'll learn how to measure caster specifications accurately. We'll walk through each measurement step, explain why it matters, and show you what tools you need. By the end, you'll know exactly how to specify the right caster for your equipment.

Key Takeaways:

Wheel diameter affects floor contact and load capacity; measure it straight across the center to ensure floor compatibility.

Stem height and mounting must match your equipment's design; wrong dimensions prevent installation or cause equipment instability.

Load capacity requires knowing the total equipment weight plus load, then dividing by the number of casters.

Swivel radius determines whether your cart can turn in tight spaces; measure your available floor space before choosing.

Brake performance and floor material compatibility prevent unexpected failures in your specific environment.

Regular re-measurement catches wear and degradation before equipment fails, reducing unplanned downtime.

Understanding Caster Measurement

Caster measurement is the process of collecting specific physical dimensions and performance specifications to select the right caster for your equipment. This includes wheel size, stem height, mounting plate dimensions, load rating, swivel capacity, and brake function.

Accurate measurement ensures the caster fits your equipment, handles your load safely, and performs in your environment without wear or failure. Understanding the definition is only the first step. Let’s explore the direct, measurable impact of precise casters on your operational safety and bottom line.

Why Accurate Caster Measurement Is Critical For Safety And Productivity

Measurement errors have direct consequences. An undersized caster fails under load. An oversized caster doesn't fit your equipment. Wrong brake specifications mean carts roll unexpectedly.

Poor floor material choices cause premature wear. Each mistake compounds into lost productivity and higher injury risk. Accurate measurement prevents these problems before they start:

Wheel Diameter's Impact on Performance

Wheel diameter determines how much weight each caster can support and how smoothly it rolls. Larger wheels distribute weight better and roll over debris more easily.

Smaller wheels fit compact equipment but may wear faster under heavy loads. Wrong diameter causes uneven wear and potential failure.

Stem Specs Prevent Installation Failures

The stem is the vertical post connecting the wheel to your equipment. If the stem height doesn't match your equipment's mounting holes, the caster won't install at all.

If the diameter is too large, it won't fit the hole. Measuring stem dimensions prevents costly installation problems.

Load Calculations Prevent Failures

Casters have maximum weight ratings. Exceeding this causes wheels to flatten, bearings to fail, and carts to become unstable.

Measuring your total load (equipment plus contents) and dividing by the number of casters ensures each one operates within safe limits.

Swivel Radius and Workspace Efficiency

Swivel radius is how much space your caster needs to turn. A tight swivel radius lets equipment turn in small spaces. A wide radius requires more floor space.

Measuring your workspace prevents you from ordering casters that can't turn in your aisles or hallways.

To execute these accurate measurements and prevent costly mistakes, you must first know the caster's anatomy and what each component controls.

Understanding The Caster Parts Before You Measure

Casters have multiple components, and each one affects how they function in your operation. Understanding what you're measuring ensures you capture the right data and choose casters that actually work for your needs.

Missing one dimension creates problems down the line.

Wheel Diameter and Material: Measure straight across the center. Material choice matters: polyurethane for hard floors, rubber for smooth surfaces, specialty materials for cold or wet environments.

Stem Height, Width, and Threads: Height determines caster sit height above the mounting plate. Width affects load distribution. Thread type (threaded vs. plate mount) determines attachment method.

Mounting Plate and Bolt Pattern: Measure the distance between bolt holes to ensure alignment with existing holes. Wrong spacing requires drilling new holes or results in loose casters.

Swivel Radius: Swivel radius is measured from the center to the wheel's farthest point when rotating. Determines your turning space requirements. Rigid casters don't swivel but offer better straight-line stability.

Brake Type and Holding Strength: Common types include foot brakes, total-lock brakes, and pressure-release brakes. Holding strength varies by type. Your choice depends on the floor slope and rolling prevention requirements.

With a clear understanding of the components, you are ready for the definitive, hands-on guide. Follow these six steps for a perfect measurement.

Step-by-Step Process: How To Measure A Caster

This is the most critical part of the process. Following these steps ensures you gather the data needed to source the exact replacement or upgrade. Do not skip steps, as a single missing dimension can make a new caster unusable.

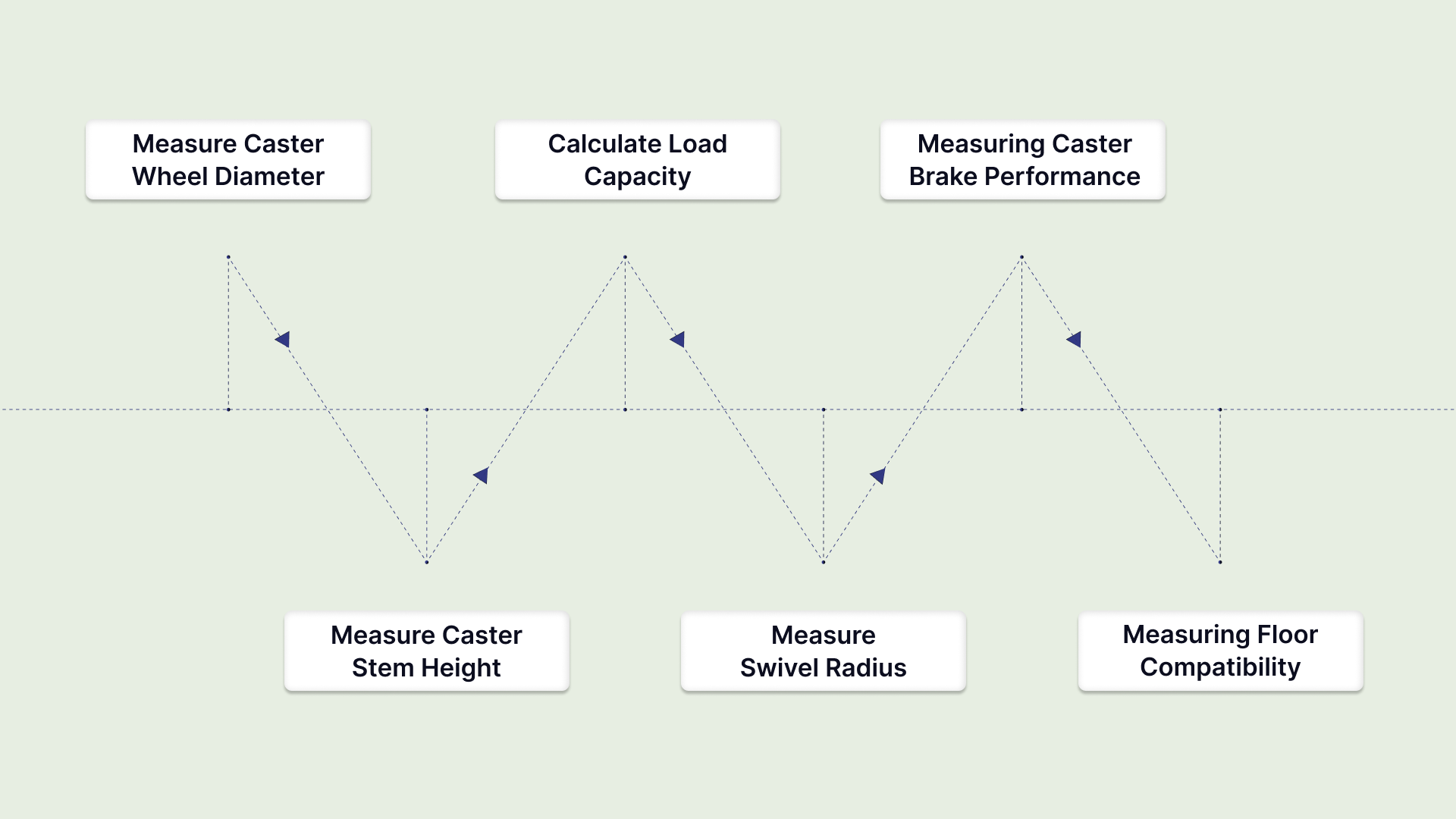

Step 1: Measure Caster Wheel Diameter

Wheel diameter determines load capacity and floor compatibility. The wrong size either fails under load or doesn't fit your equipment space.

What you should do:

Place the caster on a flat surface.

Use a tape measure to measure straight across the wheel center (not the edge).

Record the measurement in both inches and millimeters.

Measure three different spots around the wheel to check for uneven wear.

If measurements vary, the wheel is worn and needs replacement.

What to expect after this step: You'll know your wheel's actual diameter. If the wheel is worn (measurements vary by more than 1/8 inch), you've found the replacement problem. A new caster with the same diameter maintains your equipment's current height and stability.

Step 2: Measure Caster Stem Height and Mounting Dimensions

The stem must match your equipment's mounting holes. Wrong measurements mean the caster doesn't install or sits at an angle.

What you should do:

Measure from the bottom of the wheel to the top of the stem (total height).

Measure the stem diameter (width) using calipers if possible.

Find the mounting plate. Measure the distance between bolt holes (both length and width).

Count the bolt holes and note their pattern (4-hole square, 2-hole rectangular, etc.).

Measure the distance from the stem center to each bolt hole.

What to expect after this step: You'll have a complete mounting profile. Compare these measurements to your current caster if you're replacing one, or to your equipment's specifications if you're adding new casters. Matching dimensions ensures the new caster fits your holes without modification.

Step 3: Calculate Load Capacity and Weight Distribution

Casters have weight limits. Exceeding them causes failure and creates safety hazards. This calculation ensures each caster carries its fair share.

What you should do:

Weigh your empty equipment on a scale (or estimate from manufacturer specs).

Add the typical load you carry (boxes, parts, materials, etc.).

Add the weight of workers who might ride on or push the equipment.

Write down the total weight.

Count how many casters support the equipment (usually 4).

Divide the total weight by caster count. This is your weight per caster.

Confirm this number is below the caster's rated capacity (printed on the caster or in product specs).

What to expect after this step: You now know the load each caster must handle. If your current casters are rated lower than this number, that's why they're failing. Choosing casters with higher ratings prevents future failures.

Step 4: Measure Swivel Radius and Turning Space

The Swivel radius determines whether your equipment can turn in your workspace. Inadequate space causes damage and slows operations.

What you should do:

Find your tightest turning space (a narrow hallway, stairwell, or aisle).

Mark the current caster position on the floor with chalk or tape.

Rotate the equipment slowly through its full 360-degree turn.

Mark where the farthest part of the wheel reaches.

Measure the radius from the center mark to the outer mark.

Compare this to your available space. The caster radius must be smaller than your space.

What to expect after this step: You know whether your casters fit your turning requirements. If they don't, you need casters with a smaller swivel radius (often rigid or fixed casters, which don't swivel) or you need to change your equipment's path through your workspace.

Step 5: Measuring Caster Brake Performance and Lock Mechanisms

Brakes prevent carts from rolling unexpectedly. Poor brake performance causes injuries and product loss. Testing ensures brakes work reliably.

What you should do:

Load your equipment to the maximum working weight.

Place it on the slope or incline where it normally sits.

Apply the brake fully.

Attempt to push the cart by hand. It should not move at all.

If it moves, the brake is worn or incorrectly adjusted.

Check the brake lever for smooth operation (no sticking or grinding).

Document whether the brake holds on your steepest slope.

What to expect after this step: You'll know if your brakes are reliable. A cart that rolls after braking indicates brake wear or incorrect adjustment. This is a safety hazard that needs immediate attention. Properly functioning brakes hold the cart stationary even on sloped floors.

Step 6: Measuring Floor Compatibility and Caster Material

Wrong wheel material damages floors or wears out quickly. Testing prevents both problems.

What you should do:

Identify your floor type (concrete, polished tile, linoleum, epoxy, etc.).

Note if floors are wet, dry, hot, or cold regularly.

Check your current caster wheel material (polyurethane, rubber, nylon, phenolic, etc.).

Look for marks or scratches left by the caster on your floor.

Examine the wheel for uneven wear patterns or hardening.

Test the wheel's hardness by pressing your fingernail into it. Soft materials indent easily.

If wear is uneven or floors are marked, the material is incompatible.

What to expect after this step: You understand which wheel material works in your environment. Choosing the right material prevents premature wear and floor damage. In harsh environments (cold storage, wet areas, high heat), specialty materials often last 2–3 times longer than standard options.

Just completed your measurements? Send your specifications to our team for a custom-manufactured caster to your specifications. Contact us now.

The step-by-step process is crucial, but successful measurement also means anticipating the common errors that often sideline procurement teams.

Common Caster Measurement Mistakes

Teams often make predictable mistakes when measuring casters. These errors result in ordering the wrong replacements, wasting time, and repeating the process. Knowing these pitfalls helps you avoid them the first time.

Measuring wheels without accounting for wear

Worn wheels are smaller than the original specifications. Measuring a worn wheel and ordering the same size gives you a caster that sits higher than your current one.

This changes equipment clearance and stability. Always compare to original specs or consider this height difference when ordering.

Ignoring the total load, including workers and temporary cargo

Many teams measure only the equipment weight, not what they actually load on it. Peak loads, including workers standing on platforms or temporary heavy items, create stress that the basic measurement misses. Always measure at the maximum realistic load.

Mixing up stem height with total caster height

Stem height (the vertical post) is different from total caster height (wheel bottom to mounting plate top). Ordering by total height can result in stems that are too long or too short. Measure from the wheel center to the mounting plate top, not from the floor to the top.

Failing to re-measure casters showing visible wear

Casters don't last forever. Wheels flatten, swivel mechanisms loosen, and brakes wear out. Measuring worn casters and ordering identical replacements gets you the same tired performance. Measure original specifications instead, and consider upgraded materials for harsh environments.

Don't let a small error derail your project. We work with caster and wheel factories around the globe, ensuring we can provide the precise caster at the correct performance level. Explore our range of casters here.

Beyond general measurement pitfalls, the environment of your facility dictates unique requirements that must be factored into your final specification.

Overlooking Environment-Specific Requirements

Casters in cold storage, wet kitchens, or chemical plants face conditions standard casters can't handle. Measuring dimensions alone misses the material compatibility issue. Always document your environment (temperature, humidity, chemicals, cleanliness standards) and verify material compatibility.

Manufacturing Plants: Measure during peak shifts to capture realistic maximum loads. Track replacement frequency: if casters fail every 8 months, upgrade specs or maintenance to extend life to 18+ months.

Healthcare Facilities: Test wheels on your specific floors and measure noise levels. Verify equipment height meets patient handling standards, and brake performance works on sloped hallways.

Cold Storages: Test wheel hardness and swivel movement at operating temperature. Plan for frequent replacement since temperature cycling causes faster material failure than constant cold.

Food and Beverage: Measure caster design for bacteria-hiding gaps and verify stainless steel components. Confirm drainage design prevents liquid pooling and all materials meet food-safe standards.

Meeting these specialized, industry-specific demands is often impossible with generic or off-the-shelf solutions found in standard catalogs.

Why Off-The-Shelf Solutions Might Fail You

Sourcing the right caster is difficult when you rely on generic catalogs. Standard distributors often lack the specific dimensions or load ratings required for specialized industrial applications, leaving you with parts that "almost" fit but eventually fail.

Humphries Casters provides the solution by bridging the gap between global sourcing and custom engineering. Here’s why you should choose us:

Global Reach: Access to 400+ factories allows us to match your exact measurements with precision parts, not just "close enough" alternatives.

Custom Fabrication: If standard measurements don't align, we manufacture custom mounting plates and stems to fit your unique equipment.

Safety Focus: We review your load calculations and environmental data to recommend solutions that reduce injury risks.

Consultative Service: We don't just ship parts; we verify that your measurements translate to operational success.

We ensure your mobility equipment meets your specific safety and efficiency goals.

Wrapping Up

Accurate caster measurement is the foundation of a safe and efficient workplace. Whether you are refitting a warehouse fleet or designing new OEM equipment, taking the time to measure wheel diameter, bolt patterns, and load capacity correctly prevents downtime. It turns a simple maintenance task into a long-term operational upgrade.

Humphries Casters ensures you get the right component for the job, every time. We combine deep technical expertise with a vast supply network to solve your toughest mobility challenges.

Ready to improve your facility's safety and uptime? Contact Humphries Casters today for your material handling needs.

FAQs

Q. How do I measure the stem size of a caster?

Use digital calipers to measure the diameter of the stem. For threaded stems, you must also determine the thread pitch (threads per inch). Measure the length of the stem from the base (where it meets the caster) to the top.

Q. What is the difference between plate and stem casters?

Plate casters use a flat bracket with four bolt holes to mount to the equipment, offering high stability for heavy loads. Stem casters use a single rod (threaded or grip ring) to insert into a leg or socket, typically used for lighter carts and furniture.

Q. How do I calculate the load capacity I need per caster?

Take the total weight of the equipment plus the maximum load it will carry. Divide that number by the number of casters minus one (usually 3 for a 4-wheel cart). This safety margin accounts for uneven floors where one wheel might lose contact.

Q. Why is the swivel radius measurement important?

The swivel radius is the distance from the center of the mount to the furthest point of the wheel. If this distance is too large, the wheel will hit the cart's leg or frame when it swivels, preventing the cart from turning or steering properly.

Q. Can I replace a 4-inch caster with a 5-inch caster?

Yes, if you have enough vertical clearance and the mounting pattern matches. A larger wheel will roll more easily over debris and obstacles, but it will raise the total height of the cart, which might impact ergonomics or fit under tables.