You’ve just pulled out a stubborn engine from a bay: heavy, oily, awkward to maneuver, and now comes the tricky part: getting it onto an engine hoist. One wrong move and you risk a cracked floor, a bent engine block, or worse, much more work than you bargained for. That’s where engine hoist casters step in.

These are not just wheels; they’re the difference between a smooth, controlled move and a messy, dangerous lift.

This post gives you a quick, practical guide to what engine hoist casters are, how to choose the right ones, and how to keep your hoist moving safely and smoothly.

At a Glance:

Caster Choice Drives Performance: The right engine hoist casters improve control, stability, and movement under heavy load.

Match to Real Conditions: Floor type, load profile, and movement frequency determine which caster works best.

Different Types, Different Benefits: Steel/cast-iron, polyurethane/rubber, heavy-duty metal, and specialty casters solve different workshop challenges.

Upgrade Signals: Hard steering, uneven rolling, and vibration are early signs your hoist needs better casters, not a new hoist.

Expert Support Helps: Humphries Casters & Supplies guides selection for safer handling, smoother workflow, and longer equipment life.

Engine Hoist Casters: What They Are & Selection Criteria

Engine hoist casters are the wheels mounted at the base of an engine crane, allowing it to roll and reposition under load. Simple idea. High stakes.

When you’re handling engines that weigh hundreds of pounds, mobility isn’t optional. Engine hoist casters control how smoothly the hoist moves, how stable it feels, and how safely the load travels across the shop floor. Poor casters make steering difficult, increase strain on technicians, and can damage floors or compromise control when the hoist is fully loaded.

Before choosing replacement or upgraded engine hoist casters, these are the key selection factors that decide real-world performance:

Selection Factor | What It Means in a Workshop Context | Why It Matters for Engine Hoists |

Load Capacity (Total System Weight) | Combined weight of hoist, engine, accessories, fluids, and tools | Prevents caster failure under real load conditions; supports safe lifting without strain or collapse |

Wheel Material / Tread Type | Rubber, polyurethane, steel, cast iron, or hybrid materials | Affects rolling smoothness, noise, floor protection, and durability on concrete, epoxy, oily floors, or uneven surfaces |

Wheel Diameter & Width | Size and contact area of the wheel | Larger and wider wheels roll more easily under heavy loads and handle debris, cracks, and surface imperfections |

Swivel vs. Rigid Configuration | Turning ability and steering control setup | Better maneuverability during engine alignment and tight shop spaces; reduces effort during repositioning |

Bearing Type & Rolling Efficiency | Ball, roller, or precision bearings | Low-resistance movement under heavy loads: easier steering, less operator fatigue, smoother travel |

Floor Environment | Shop surface conditions: smooth, rough, dirty, oily, or finished | Controls grip, safety, noise, and floor protection; avoids skidding, wheel lockup, or surface damage |

Braking & Locking Options | Swivel locks or wheel brakes | Keeps hoist steady during lift or alignment; prevents unwanted movement under suspended loads |

Mounting Compatibility | Plate or stem size, bolt pattern, and fit with existing hoist | Avoids modification issues and ensures fast installation or replacement without downtime |

Durability & Maintenance Needs | Resistance to wear, chemicals, impact, and debris | Reduces replacement frequency, supports consistent workshop uptime, cuts long-term operating costs |

Once you know what to look for, the next step is choosing the type of caster that fits how your shop really operates.

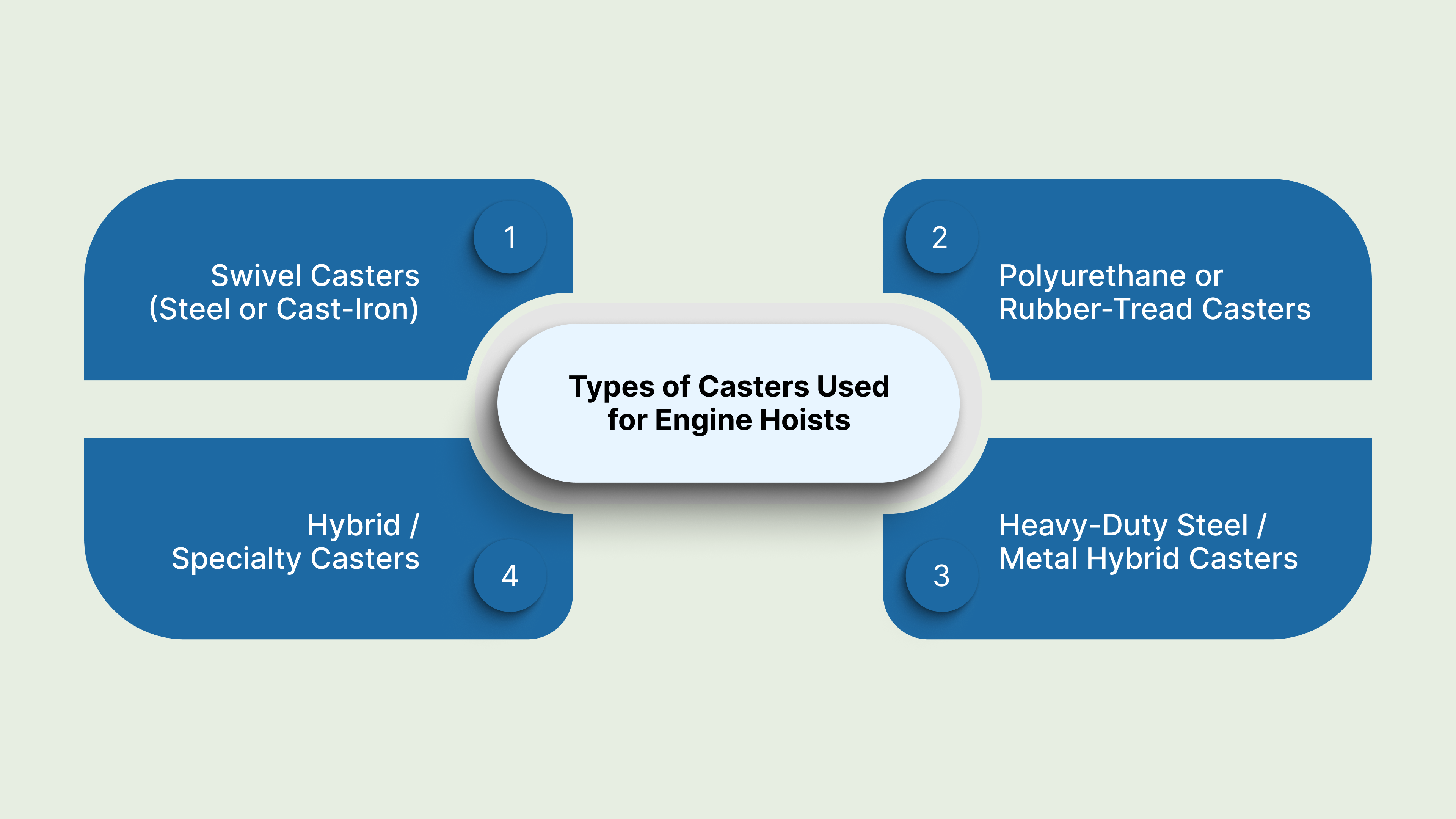

Common Types of Casters Used for Engine Hoists

Not every caster works the same under load, on different floors, or in tight spaces. The right choice depends on how often you move the hoist, what surfaces you roll across, and how close you run to maximum load.

Here are the most common options you’ll come across in real workshop use:

1. Swivel Casters (Steel or Cast-Iron)

Swivel casters rotate 360°, allowing the engine hoist to change direction easily and maneuver in tight spaces. Steel or cast-iron wheels provide high strength for demanding workshop loads and rougher shop environments.

Best suited for

Workshops that frequently reposition hoists in tight or crowded bays

Heavy engines and high-load applications where strength and durability are critical

Concrete floors or tough industrial shop surfaces where impact resistance matters

Operational advantages

Precise steering control under load — easier alignment when dropping an engine into mounts or rolling between lift areas.

Handles heavy static and rolling loads reliably — supports consistent performance without flexing or flattening.

Survives abrasive floor conditions and debris — reduces risk of wheel chips or premature wear in tough shop spaces.

Low rolling resistance — requires less physical force to move fully loaded hoists.

Considerations/limitations

Not ideal for finished or epoxy-coated floors if floor protection or noise reduction is a priority

Hard metal wheels can transmit vibration; they may feel harsh on uneven surfaces

It can produce more noise than softer wheel materials when the equipment is moving

Ideal for

Performance and rebuild shops handling large displacement engines

Heavy-equipment mechanics and industrial fleet service teams

Workshops where durability and maneuverability matter more than floor-friendliness or noise level

2. Polyurethane or Rubber-Tread Casters

Polyurethane or rubber-tread casters use a softer, floor-friendly wheel surface designed for smooth, quiet rolling and better grip. They’re built to protect shop floors while still managing substantial load requirements on engine hoists.

Best suited for

Workshops with epoxy-coated, tiled, or polished concrete floors

Areas where noise control matters (indoor service bays, dealerships, training centers)

Frequent movement of hoists across clean, level surfaces

Operational advantages

Smooth, controlled movement under load — reduces push effort and improves handling accuracy when aligning engines.

Protects floors from scratches or chips — avoids costly surface repair or coating failure.

Quieter rolling lowers noise exposure in enclosed shop environments.

Better grip on oily or slightly slick surfaces — supports safer repositioning during precision work.

Reduced vibration transfer — helps retain stability when moving a suspended engine.

Considerations/limitations

Not the best option for rough or debris-heavy floors; tread can wear faster in harsh environments

May feel softer under extremely heavy loads compared to steel or cast-iron wheels

Can pick up metal shavings or sharp debris if the floor is not maintained regularly

Ideal for

Automotive repair shops, dealership service centers, specialty tuning shops

Workspaces where customer visibility and cleanliness matter

Mechanics handling frequent but controlled moves rather than extreme load conditions

3. Heavy-Duty Steel / Metal Hybrid Casters

Heavy-duty steel or metal-hybrid casters combine a reinforced metal wheel with high-strength bearings and robust mounting hardware. They’re built for extreme loads, harsh shop environments, and demanding movement conditions where equipment reliability is non-negotiable.

Best suited for

Shops working on diesel engines, commercial fleet engines, or industrial equipment

Rough concrete or uneven workshop floors with debris, expansion joints, or surface damage

Low-speed, high-load movement where brute strength and durability take priority

Operational advantages

Handles maximum load conditions safely — supports larger engines and full-weight hoist movement without compression or deformation.

Highly resistant to heat, impact, metal debris, and floor imperfections — keeps rolls predictable and avoids sudden wheel failure.

Low maintenance lifecycle — designed to last longer under heavy daily use and abrasive environments.

Reliable performance during static holds — avoids flat-spotting when a hoist stays loaded for long periods.

Considerations/limitations

It can be loud and uncomfortable to roll on hard floors

Not ideal for finished, polished, or sensitive floor surfaces

Requires more effort to push if the floor is not well-maintained

Ideal for

Heavy-duty diesel repair facilities, industrial engine rebuilders, fleet maintenance shops

Operations where durability and uptime matter more than noise or floor aesthetics

Mechanics frequently move hoists under near-capacity or uneven load conditions

4. Hybrid / Specialty Casters

Hybrid or specialty casters are engineered for specific performance needs, combining unique wheel materials, shock-absorbing features, or non-standard designs to solve challenges that standard casters can’t. They’re built for shops with unusual floor conditions, precision-critical work, or mobility obstacles.

Best suited for

Shops with uneven floors, ramps, thresholds, or surface transitions

Work environments requiring low-vibration movement for sensitive components or precision alignment

Situations where specialized resistance is needed (chemical exposure, heat, moisture, metal debris)

Operational advantages

Improved stability with shock-absorbing or spring-loaded options — reduces bounce and sway when repositioning a hoist under load.

Enhanced control over rough or interrupted surfaces — smoother travel over seams, drains, or expansion joints.

Material options for extreme environments — high-temperature resistance, chemical-safe compounds, or debris-tolerant wheel profiles.

Non-magnetic or corrosion-resistant variants — useful in specialty automotive, marine, or lab-adjacent work areas.

Better ergonomic handling — lower push force and reduced operator fatigue in complex movement paths.

Considerations/limitations

Higher investment compared to standard caster options

Performance benefits depend on correct matching with the actual work environment, require proper selection guidance

May not be necessary for light-duty or straightforward shop layouts

Ideal for

Custom fabrication shops, performance engine builders, R&D, and prototype workshops

Mixed-floor facilities with indoor/outdoor movement paths

Teams that move heavy hoists frequently and need smooth motion without sacrificing control or safety

Looking for actual caster options that match your shop's needs? Check out our full range on our Casters & Wheels page.

Choosing the right caster is only half the job. How you use and maintain them determines how long they last.

Best Practices for Using Engine Hoist Casters in a Workshop

Even the best engine hoist casters won’t perform well if they’re used the wrong way. Small mistakes can turn into real safety risks, wasted effort, or damaged equipment. A few simple habits can keep movement controlled, extend caster life, and protect both people and floors.

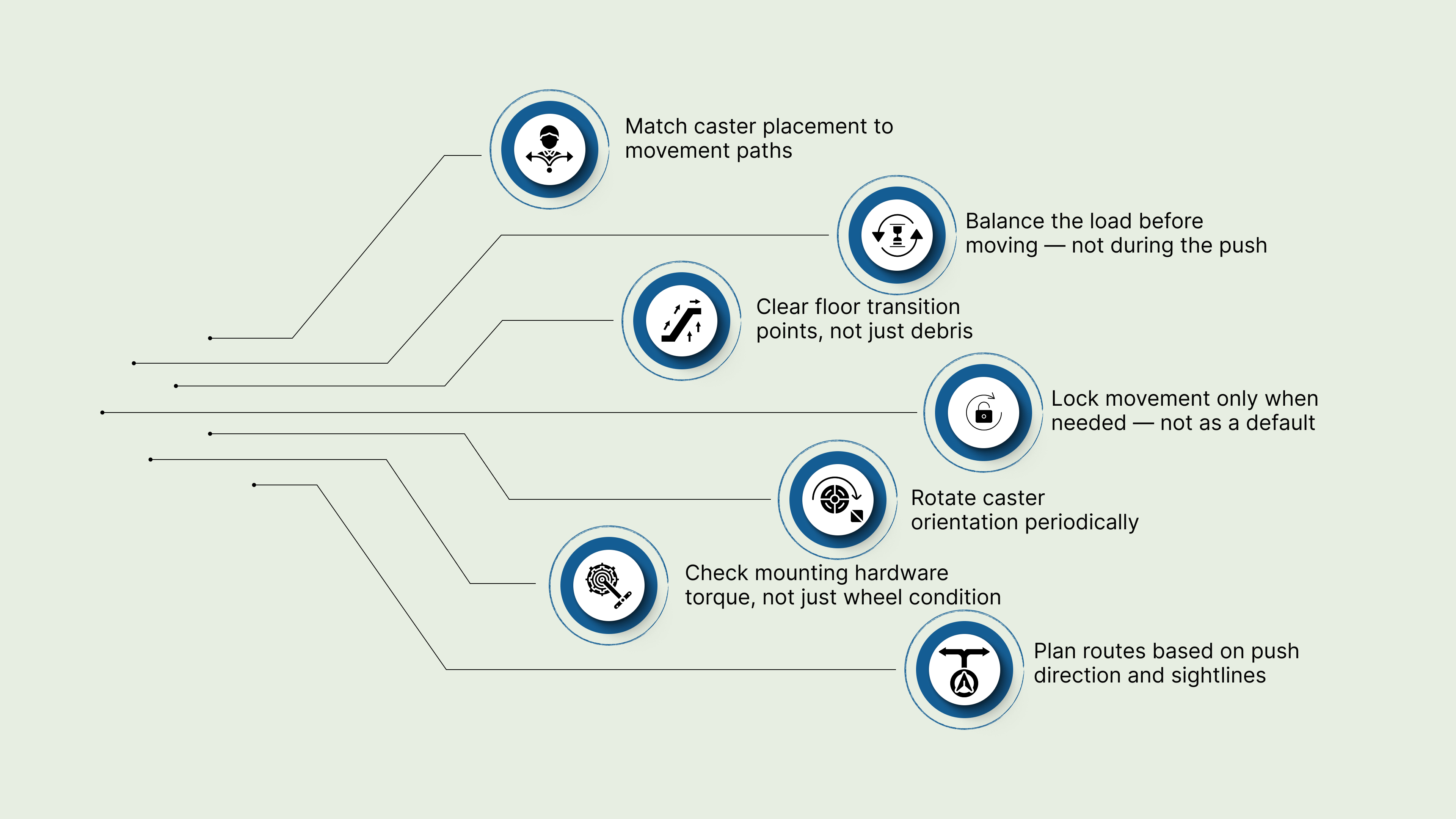

Here’s what to keep top of mind in daily shop use:

Match caster placement to movement paths

Position swivel casters at the front or rear, depending on how your team typically moves the hoist. Setup influences steering control and keeps alignment predictable when guiding an engine into mounts.

Balance the load before moving — not during the push

Adjust the level and center of gravity before repositioning. Prevents sudden shifts that strain casters and force corrective steering under load.

Clear floor transition points, not just debris

Drain channels, expansion joints, and threshold lips are common failure spots. Planning routes around them reduces shock impact and bearing stress.

Lock movement only when needed — not as a default

Brake engagement increases resistance and uneven drag if accidentally left on. Use only during alignment, not rolling.

Rotate caster orientation periodically

If the hoist sits loaded in one direction for long periods, rotate swivel casters to avoid permanent pressure patterns and uneven wear.

Check mounting hardware torque, not just wheel condition

Bolts loosen gradually from vibration and directional force. A secure mount improves tracking, reduces caster flutter, and prevents sudden instability.

Plan routes based on push direction and sightlines

Reduces stop–start adjustments that strain bearings and increase risk during tight maneuvers. Predictable travel means less steering correction and smoother handling.

A one-size-fits-all caster rarely performs well in real shop conditions. That’s where having a knowledgeable supplier makes a difference.

How Humphries Casters & Supplies Can Help

Humphries Casters offers a wide range of heavy-duty and specialty caster options suitable for engine hoists and other shop equipment. For workshops handling different engine sizes, floor surfaces, or movement demands, having access to the right caster type matters.

The right selection guidance can significantly improve handling, stability, and day-to-day workflow efficiency.

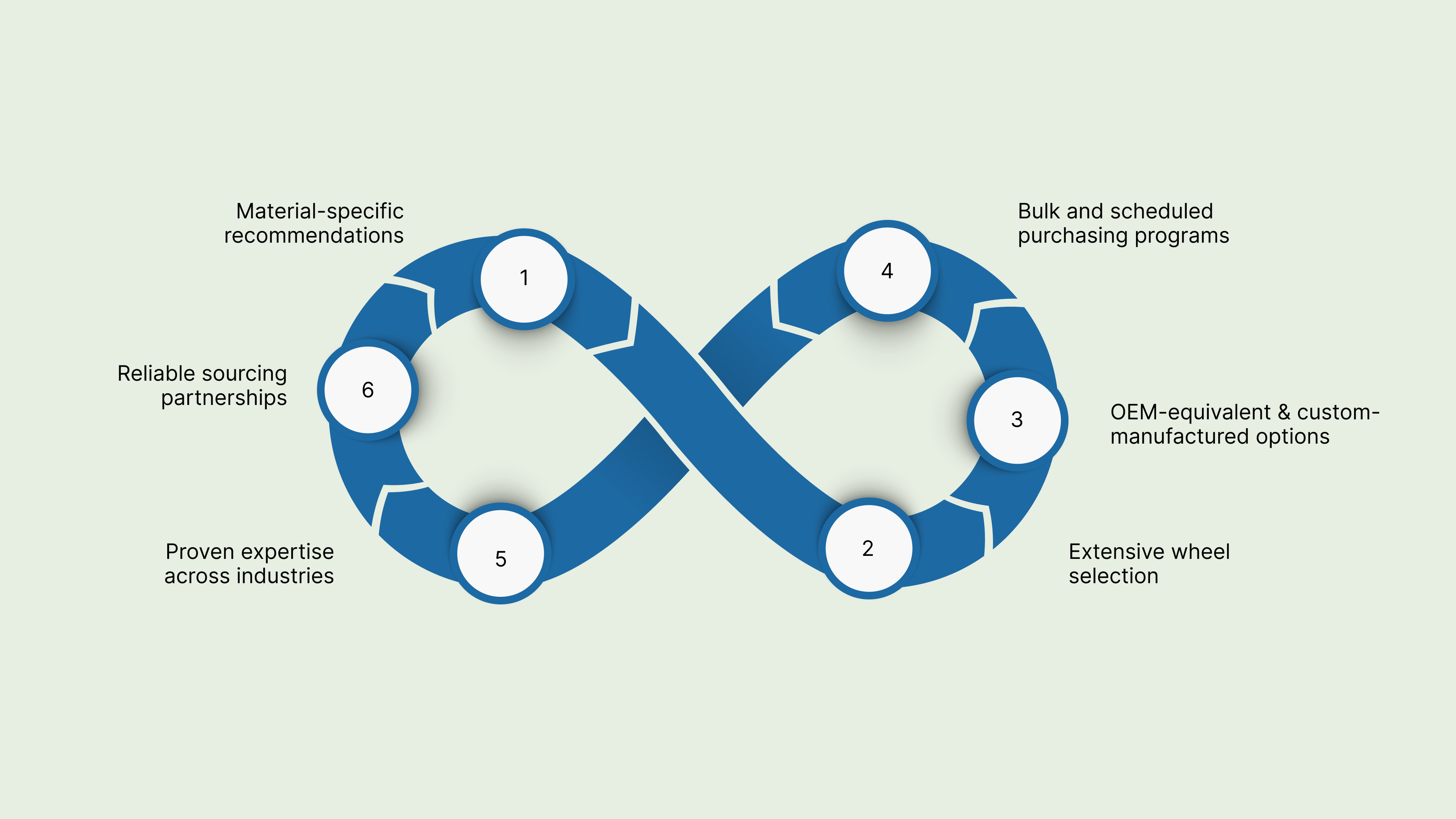

What You Can Expect From Humphries Casters

Material-specific recommendations based on load type, terrain, speed cycles, sanitation requirements, and usage frequency.

Extensive wheel selection, including polyurethane, urethane, and specialty compounds engineered for harsh or regulated environments.

OEM-equivalent and custom-manufactured options to ensure compatibility and eliminate modification delays.

Bulk and scheduled purchasing programs for multi-location facilities, warehouses, and high-cycle operations.

Proven expertise across industries, including hospitals, food-processing, distribution centers, assembly lines, and transport logistics.

Reliable sourcing partnerships with access to hundreds of manufacturing facilities for rapid fulfillment and application testing.

Our team helps evaluate load requirements, floor conditions, movement paths, and durability needs.

This supports safer, smoother hoist mobility and longer equipment life without overspending or over-specifying.

Conclusion

Engine hoist casters may seem minor, but they influence workflow more than most shop owners realize. The right setup makes movement predictable, reduces strain, and keeps work flowing smoothly, especially when every bay minute matters.

If maneuvering a loaded hoist feels harder than it should, or your current casters are slowing down the job, it’s worth rethinking what’s under the hoist.

Need help choosing the right setup? Reach out to us, and we’ll recommend the best fit for your shop and workload.

FAQs

1. What’s the biggest mistake mechanics make when replacing engine hoist casters?

Choosing casters based only on wheel size or price instead of matching them to real load conditions and floor environments. That’s where most performance issues begin.

2. Why do some hoists feel harder to push even when the casters look brand-new?

The issue is often in bearings or mounting alignment, not the wheel surface. Misalignment creates drag that feels like weight gain, even on a clean floor.

3. How do I tell if my hoist’s caster problem is a wheel issue or a floor issue?

Test movement on a clean, unobstructed section of floor. If resistance changes significantly compared to normal use, floor texture or damage may be the bottleneck.

4. Should all casters match, or can mixing different types improve performance?

A mix of swivel and rigid casters can dramatically improve control and steering accuracy — especially for tight spaces or alignment-critical work.

5. Do caster failures usually happen suddenly or slowly over time?

Most degrade gradually through hidden bearing wear or bolt loosening, not visible wheel damage, which is why performance changes before obvious failure.