If you have vinyl plank flooring in your home, office, or workplace, you already know how great it looks and how easily it can get scratched, dented, or marked if the wrong wheels roll across it. That’s why choosing the best casters for vinyl plank flooring matters.

In this guide, you’ll learn exactly what to look for when selecting casters for vinyl floors, which materials work best, and which types to avoid.

Let’s start with why vinyl flooring requires special caster consideration.

Key Takeaways:

Material Matters: Soft polyurethane, TPR, and wide-tread casters are the best casters for vinyl plank flooring because they protect against scratches, dents, and seam damage.

Avoid Hard Wheels: Hard plastic, nylon, and metal casters can dig into vinyl surfaces and leave permanent marks or compression tracks.

Match Casters to Use Case: Different environments need different caster types—soft swivel for office, locking soft PU for medical, wide-tread for heavy carts.

Movement + Maintenance Count: Clean wheels, proper weight distribution, and avoiding dragging prevent surface wear long-term.

Smarter Selection Saves Money: The right casters reduce repair costs, protect aesthetics, improve mobility, and extend the lifespan of vinyl flooring.

Why Vinyl Plank Flooring Needs the Right Casters

Vinyl plank flooring is durable, but it isn’t designed to handle concentrated pressure or abrasive wheel contact. Because the material is softer and more flexible than tile or concrete, the wrong casters can create deep dents, scuffs, seam separation, or long-term wear patterns that can’t be undone.

When you align wheel material, tread softness, and load capacity with the floor’s characteristics, you prevent damage before it starts and extend both the appearance and lifespan of the flooring.

Below is a breakdown of the essential features you should look for when choosing the best casters for vinyl plank flooring:

Soft, non-marking tread materials

Soft polyurethane, thermoplastic rubber (TPR), or TPE distribute pressure evenly and prevent scuffs, scratches, and surface etching, unlike hard plastic or nylon wheels that dig into vinyl.

Wider wheel profile for load distribution

A wider tread spreads weight over a larger surface area, reducing point pressure that causes dents or plank compression.

Larger wheel diameter for smoother movement

Bigger wheels roll more easily over seams, transitions, and debris without grinding dirt into the floor or stressing plank joints.

Shock-absorption and vibration control

Cushioned wheel construction reduces impact force and protects both flooring and transported items, especially in high-use environments.

Non-scuff, easy-clean tread surface

Dirt buildup on wheel surfaces acts like sandpaper; choosing easy-clean casters prevents grit-driven micro-scratching.

Load rating matched to equipment weight

Underrated wheels dig into flooring and compress vinyl over time. Always match caster specs to the full load, including the equipment, not just the item being moved.

Now that you know the key features to look for, it’s time to translate those requirements into real caster options.

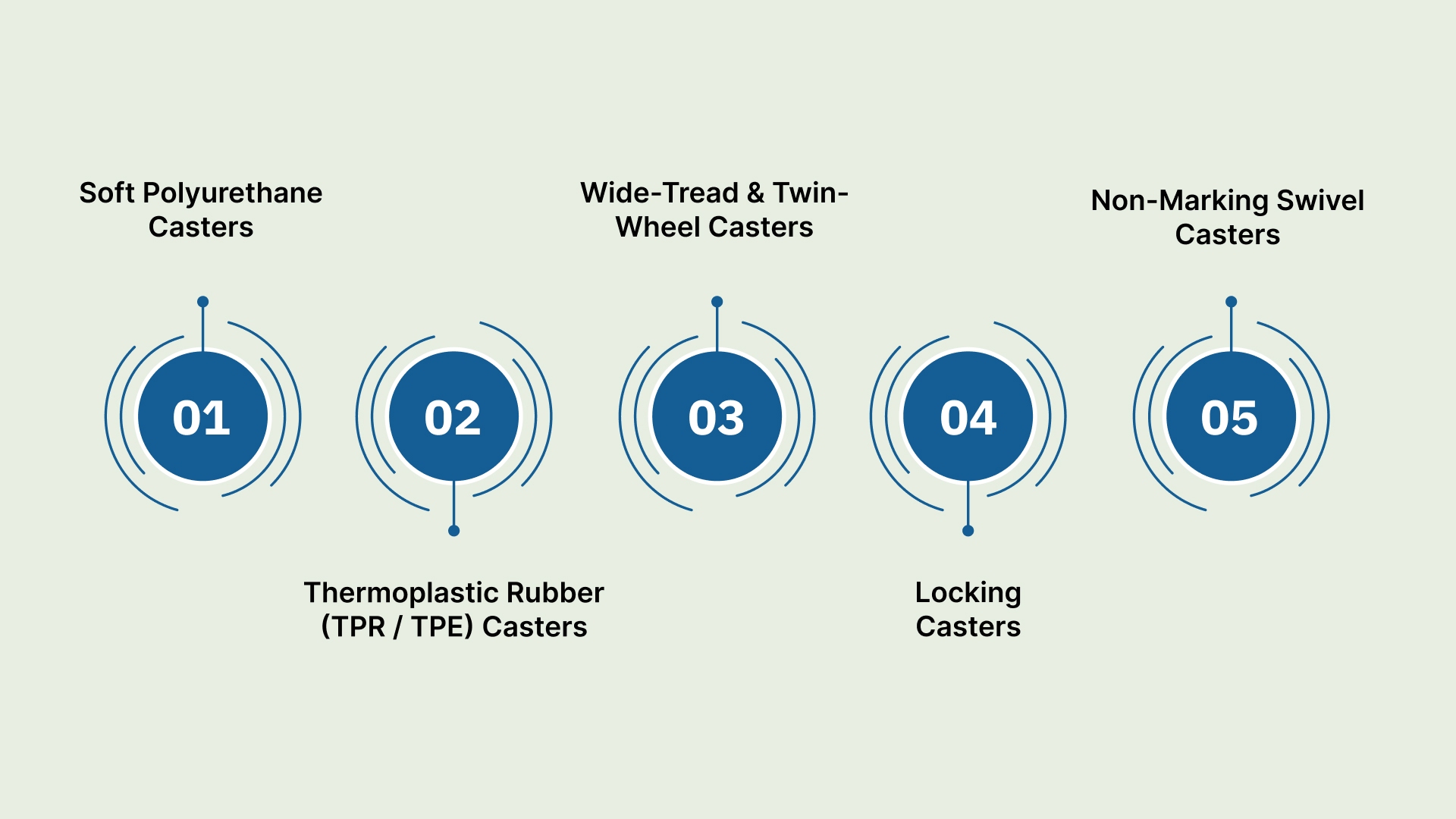

Caster Types That Work Best for Vinyl Floors

Not all wheels are built the same, and choosing the right caster type depends on how much weight you’re moving, how often the equipment rolls, and what environment it operates in.

The caster styles below offer the best protection and performance on vinyl plank flooring while preventing damage over long-term use.

Soft Polyurethane Casters

Soft polyurethane casters provide a balance of strength, smooth rolling, and superior floor protection. Their softer tread absorbs shock and reduces vibration, which keeps vinyl surfaces safe from compression and prevents abrasive wear that creates dull track lines over time.

Best Environments & Use Cases

Hospitals & healthcare facilities — ideal for medical carts, patient transport equipment, supply carts

Corporate offices — office chairs, mobile desks, computer carts, filing cabinets

Retail & hospitality — display fixtures, rolling furniture, food service equipment

Education spaces — lab tables, AV carts, mobile classroom furniture

Why Choose This Type

Quiet rolling in noise-sensitive environments

Protects polished or decorative vinyl finishes

Suitable for moderate to heavy loads without floor damage

Thermoplastic Rubber (TPR / TPE) Casters

TPR and TPE casters provide maximum softness and floor contact, making them the gentlest wheel option for vinyl plank flooring. They resist marking and reduce slip-and-scratch risk when equipment turns sharply or rotates frequently.

Best Environments & Use Cases

Medical & lab environments — sensitive equipment requiring precise mobility

Hospitality & residential spaces — lightweight furniture and décor items

Customer-facing environments — retail floors, showrooms, cafes, boutique hotels

Museums & art spaces — environments where visual floor quality must remain pristine

Why Choose This Type

Best protection for delicate vinyl plank and high-end flooring finishes

Ideal when noise reduction and soft rolling are essential

Reduces the risk of scuffs caused by quick turns or repositioning

Wide-Tread & Twin-Wheel Casters

Wide-tread and split-wheel casters spread load forces across a larger surface area. This prevents sharp pressure points — the main cause of dents and seam failure in vinyl plank flooring. Dual wheels also improve steering control under heavy loads.

Best Environments & Use Cases

Warehouses & distribution centers where vinyl plank flooring extends into office or showroom areas

Service & utility carts transporting tools, stacked goods, or heavy instrumentation

IT or AV equipment where weight is compact but high (rack units, printers, servers)

Laboratories & R&D facilities requiring smooth but heavy rolling equipment

Why Choose This Type

Prevents denting and stress cracking in vinyl seams

Handles heavy and repetitive movement without floor wear

Maintains directional control over long routes

Locking Casters

Locking casters provide secure stability when equipment needs to remain stationary. They prevent wheels from grinding into vinyl under pressure shifts, which is a common cause of surface indentation and rolling track marks.

Best Environments & Use Cases

Medical beds, hospital equipment, and lab machinery

Retail displays and merchandising fixtures

Photography, production, or lighting equipment

Portable workstations & tool cabinets

Why Choose This Type

Prevents micro-movement that causes indentation over time

Improves safety where weight shifts could affect balance

Protects seams and wear patterns in high-traffic zones

Non-Marking Swivel Casters

Non-marking swivel casters are designed to rotate smoothly without scuffing or twisting pressure that damages the surface film of vinyl planking.

Best Environments & Use Cases

Tight navigation spaces like exam rooms, restaurants, and retail dressing rooms

Chairs, stools, and lightweight rolling furniture

Storage units and mobile carts that frequently change direction

Why Choose This Type

Eliminates circular scuff patterns commonly caused by turning wheels in place

Enables precision control without damaging surface texture or finish

Now that you know which caster types protect vinyl plank flooring best, the next step is choosing the right option for your specific environment and workload.

How to Match Casters to Your Application

Different spaces place different demands on casters, whether that’s noise control, load capacity, mobility, or floor appearance. Matching caster design to real-world use ensures performance, safety, and long-term floor protection.

The table below makes it easy to identify the best fit based on your application.

Application / Environment | Recommended Caster Type | Why It’s the Best Fit |

Office chairs & light-duty furniture | TPR / Soft PU swivel casters | Quiet rolling, smooth turning, prevents scuff rings from rotation in place |

Hospital beds, medical carts, lab equipment | Soft PU / locking medical-grade casters | Low noise, hygienic rolling, stable under load, floor-safe with frequent repositioning |

Retail displays, hospitality furniture, décor fixtures | Soft PU aesthetic casters (non-marking) | Protects premium finishes, eliminates drag marks, maintains visual floor quality |

Heavy utility carts, warehouse transport on vinyl | Wide-tread / twin-wheel soft PU casters | Distributes load evenly, avoids denting plank seams under high weight |

IT, AV, or production equipment | Wide tread or dual-wheel locking casters | Maintains stability under compact but heavy weight, protects seams during setup changes |

Mobile workstations & tool cabinets | Soft PU locking swivel casters | Prevents rolling pressure when stationary, keeps load stable during operation. |

Chairs or equipment frequently moving in tight spaces | Non-marking 360° swivel casters | Prevents rotational scrubbing and swirl marks during pivoting and turning |

Even with the right caster type, how you use and maintain those wheels plays a major role in protecting your vinyl plank flooring over time.

Best Practices to Prevent Floor Damage

Choosing the right caster is only half the solution; how the wheels are used and maintained determines how well your vinyl plank flooring holds up over time. Even the safest, soft-tread casters can cause damage if dirt builds up, heavy loads sit too long, or equipment is moved improperly. Following a few practical habits will help you:

Keep caster wheels clean

Dirt, sand, and metal shavings trapped in wheel treads work like sandpaper and can scratch vinyl with every rotation. Regularly wipe wheels and check for debris buildup.

Avoid dragging or pivoting under heavy load

Twisting wheels in place grinds pressure into the floor and creates circular scuff patterns. Always start movement by rolling forward instead of turning from a dead stop.

Distribute weight evenly

For heavy equipment, choose carts with four casters of equal load rating and avoid placing excessive weight directly over one wheel.

Use mats or pads when equipment stays still

Even soft casters can create compression dents if heavy loads sit for long periods. Mats relieve pressure under stationary furniture or machinery.

Inspect wheels and floors regularly

Early signs like subtle grooves, dull spots, or noisy rolling indicate wheel wear or surface stress. Replacing worn wheels early prevents permanent floor damage.

With the right caster type and proper usage practices in place, the final step is choosing a supplier who understands how different wheel materials interact with flooring types.

Where Humphries Casters Comes In

Protecting vinyl plank flooring starts with choosing casters that balance load support, smooth rolling, and true floor safety. Humphries Casters brings decades of hands-on experience helping facilities, manufacturers, and businesses select the right caster solutions for sensitive flooring environments.

What You Can Expect From Humphries Casters

Material-specific recommendations based on load type, terrain, speed cycles, sanitation requirements, and usage frequency.

Extensive wheel selection, including polyurethane, urethane, and specialty compounds engineered for harsh or regulated environments.

OEM-equivalent and custom-manufactured options to ensure compatibility and eliminate modification delays.

Bulk and scheduled purchasing programs for multi-location facilities, warehouses, and high-cycle operations.

Proven expertise across industries including hospitals, food-processing, distribution centers, assembly lines, and transport logistics.

Reliable sourcing partnerships with access to hundreds of manufacturing facilities for rapid fulfillment and application testing.

Choosing the right caster doesn’t have to involve guesswork. With the right support, you can protect your flooring, improve mobility, and reduce long-term repair and replacement costs.

Conclusion

The wrong wheels can leave dents, scratches, and permanent wear marks that shorten the life of your flooring. If you want confidence in your selection and support that goes beyond catalog descriptions, Humphries Casters is equipped to guide you with real-world expertise and a wide selection of floor-safe caster solutions.

Have questions or need help choosing the best casters for vinyl plank flooring? Reach out to us for a recommendation tailored to your space and workload.

FAQs

1. Can standard office-chair wheels damage vinyl plank flooring?

Yes. Most standard office-chair casters are hard plastic and can scratch or indent vinyl over time. Switching to soft TPR or soft polyurethane casters is a safer option when choosing the best casters for vinyl plank flooring.

2. Do larger wheels protect vinyl floors better?

Generally, yes. Larger wheels distribute pressure more evenly and roll over seams and debris without digging into the flooring. This makes a difference when selecting the best casters for vinyl plank flooring for heavier equipment.

3. Can casters cause long-term floor damage even if they’re soft?

They can if they’re overloaded, dirty, or left stationary under heavy equipment. Proper load rating and maintenance are essential when choosing the best casters for vinyl plank flooring.

4. Should I use mats under stationary equipment on vinyl plank flooring?

If the equipment is heavy or stays in one place for long periods, floor pads or mats help prevent compression dents—even when using the best casters for vinyl plank flooring.

5. Are locking casters safer for vinyl floors?

Yes. Locking casters prevent micro-movement that grinds wheels into the surface over time, making them a smart feature when choosing the best casters for vinyl plank flooring for medical, retail, or commercial spaces.